filmov

tv

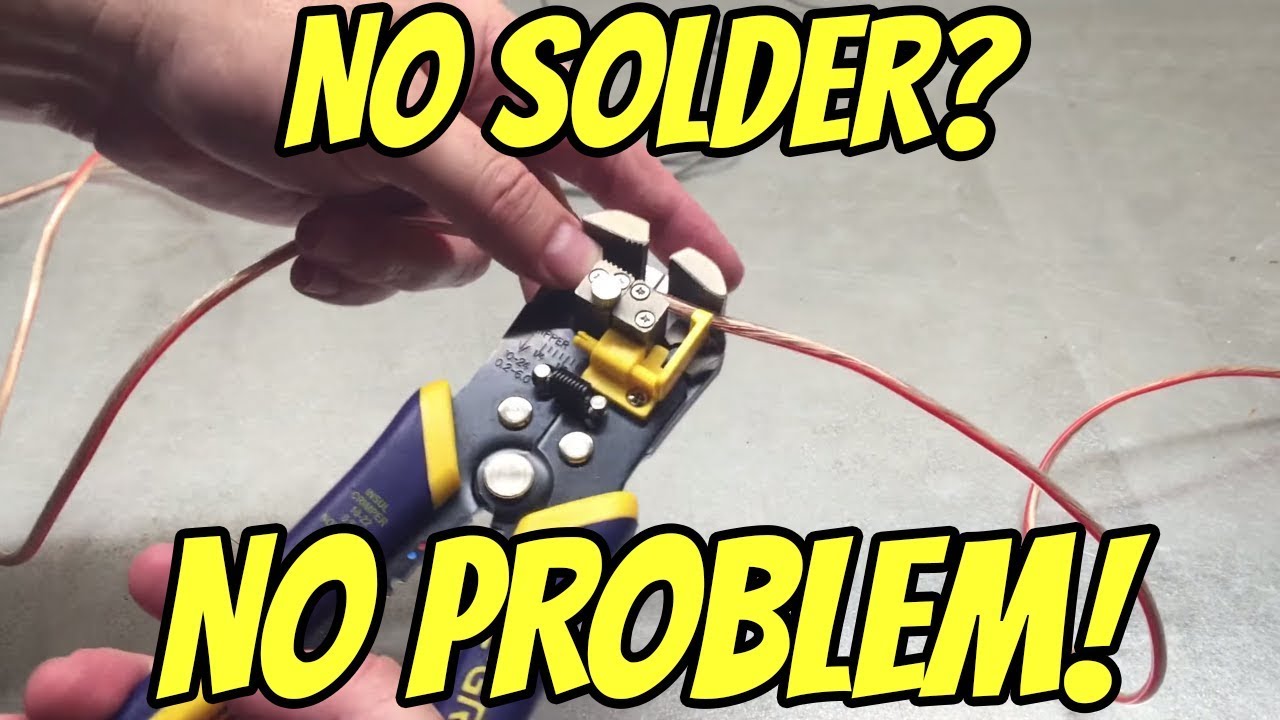

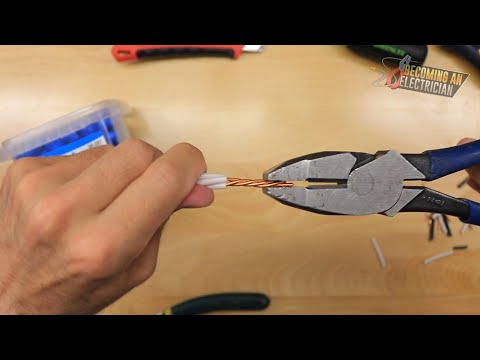

The Correct Way to T-Splice an Automotive Wire Without Solder

Показать описание

My recommended equipment for doing this:

This is my method to doing a t-splice (splicing a new wire into an existing wire) without solder. It is better to solder but this method works great and is strong if you can't solder for whatever reason.

If you cannot get heat shrink over the splice area, use one of the following:

Hope this helps someone. (I sold the company that I mentioned in the beginning of this video.)

➤ Subscribe for car stuff, how-tos, product reviews, garage life, and more:

➤ If you want to see everything that I recommend on Amazon, I made it easy for you:

➤ Armor Shield IX is the best ceramic coating available. Get yours at:

USE CODE JASONSGARAGE25 FOR $25 OFF!

(Discount applies in at checkout)

➤ Want 20% off Lamin-X? Use this link!

➤ All the cool kids Liked my Facebook page. Are you cool too?

➤ How's about Twitter?

▬ ABOUT JASON DEBLER ▬

I have been a car enthusiast since the age of 2. From watching professional drag racing to bracket racing myself and being involved in significant projects with the Chevrolet Camaro and automotive agencies, cars are my life.

▬ AFFILIATE/ADVERTISER DISCLOSURE ▬

My videos serve to entertain and educate car and garage enthusiasts, often through informative and honest product reviews and recommendations. My videos and descriptions will often contain affiliate links, which means I may earn a small commission on a purchase you make by clicking on them (at no extra cost to you, and sometimes I will help you save money).

I retain full editorial control over the content in my videos and will never make a false recommendation as a result of any form of compensation.

If you do purchase through my affiliate links, I thank you so much for your support as it allows me to continue to make helpful and entertaining videos for your enjoyment.

▬ WARNING – DON’T DO ANYTHING DUMB ▬

I do not claim to be an expert electrician, your experience and results may vary as well as opinions (no matter how rude). Standard disclaimers apply. This video is for entertainment purposes only. I assume no responsibility for any damage to watching my videos. Please be careful - the consequences of a mistake could be disastrous.

#jasonsgarage #splice #howto

This is my method to doing a t-splice (splicing a new wire into an existing wire) without solder. It is better to solder but this method works great and is strong if you can't solder for whatever reason.

If you cannot get heat shrink over the splice area, use one of the following:

Hope this helps someone. (I sold the company that I mentioned in the beginning of this video.)

➤ Subscribe for car stuff, how-tos, product reviews, garage life, and more:

➤ If you want to see everything that I recommend on Amazon, I made it easy for you:

➤ Armor Shield IX is the best ceramic coating available. Get yours at:

USE CODE JASONSGARAGE25 FOR $25 OFF!

(Discount applies in at checkout)

➤ Want 20% off Lamin-X? Use this link!

➤ All the cool kids Liked my Facebook page. Are you cool too?

➤ How's about Twitter?

▬ ABOUT JASON DEBLER ▬

I have been a car enthusiast since the age of 2. From watching professional drag racing to bracket racing myself and being involved in significant projects with the Chevrolet Camaro and automotive agencies, cars are my life.

▬ AFFILIATE/ADVERTISER DISCLOSURE ▬

My videos serve to entertain and educate car and garage enthusiasts, often through informative and honest product reviews and recommendations. My videos and descriptions will often contain affiliate links, which means I may earn a small commission on a purchase you make by clicking on them (at no extra cost to you, and sometimes I will help you save money).

I retain full editorial control over the content in my videos and will never make a false recommendation as a result of any form of compensation.

If you do purchase through my affiliate links, I thank you so much for your support as it allows me to continue to make helpful and entertaining videos for your enjoyment.

▬ WARNING – DON’T DO ANYTHING DUMB ▬

I do not claim to be an expert electrician, your experience and results may vary as well as opinions (no matter how rude). Standard disclaimers apply. This video is for entertainment purposes only. I assume no responsibility for any damage to watching my videos. Please be careful - the consequences of a mistake could be disastrous.

#jasonsgarage #splice #howto

Комментарии

0:05:03

0:05:03

0:02:48

0:02:48

0:01:34

0:01:34

0:02:00

0:02:00

0:08:28

0:08:28

0:02:27

0:02:27

0:03:38

0:03:38

0:04:25

0:04:25

0:30:08

0:30:08

0:10:44

0:10:44

0:06:38

0:06:38

0:10:01

0:10:01

0:14:22

0:14:22

0:01:30

0:01:30

0:02:12

0:02:12

0:01:47

0:01:47

0:05:37

0:05:37

0:16:36

0:16:36

0:09:10

0:09:10

0:01:29

0:01:29

0:01:00

0:01:00

0:00:58

0:00:58

0:13:33

0:13:33

0:19:47

0:19:47