filmov

tv

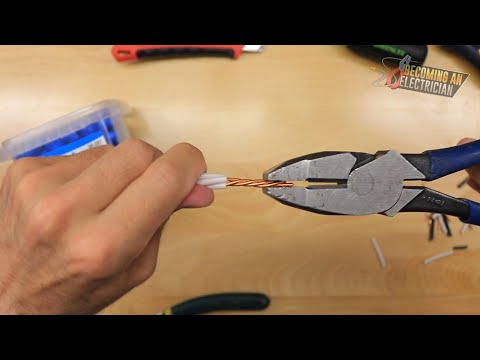

How to Splice Wires Quickly and Correctly

Показать описание

In this video I'll show you how to splice wires together using solder seal aka solder less connectors quickly. If done correctly these connectors can greatly improve your time spent splicing wires together, vs using a soldering iron.

Here are links to products which were used in this video:

Disclaimer:

Due to factors beyond the control of Ratchets and Wrenches, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. Ratchets and Wrenches assumes no liability for any property or personal damage that may arise from doing a repair on your vehicle after watching any of my repair video's. Due to factors beyond the control of Ratchets and Wrenches, no information contained in this video shall create any express or implied warranty or guarantee of any particular result. Again Any injury, damage or loss that may result from improper use of tools, equipment, or the information contained in this video is the sole responsibility of the user and not Ratchets and Wrenches.

Here are links to products which were used in this video:

Disclaimer:

Due to factors beyond the control of Ratchets and Wrenches, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. Ratchets and Wrenches assumes no liability for any property or personal damage that may arise from doing a repair on your vehicle after watching any of my repair video's. Due to factors beyond the control of Ratchets and Wrenches, no information contained in this video shall create any express or implied warranty or guarantee of any particular result. Again Any injury, damage or loss that may result from improper use of tools, equipment, or the information contained in this video is the sole responsibility of the user and not Ratchets and Wrenches.

Комментарии

0:06:38

0:06:38

0:02:00

0:02:00

0:09:10

0:09:10

0:10:01

0:10:01

0:14:22

0:14:22

0:16:36

0:16:36

0:01:42

0:01:42

0:02:48

0:02:48

0:47:57

0:47:57

0:04:25

0:04:25

0:10:44

0:10:44

0:01:00

0:01:00

0:02:12

0:02:12

0:01:29

0:01:29

0:11:06

0:11:06

0:06:08

0:06:08

0:01:00

0:01:00

0:02:16

0:02:16

0:03:38

0:03:38

0:08:28

0:08:28

0:05:03

0:05:03

0:06:11

0:06:11

0:13:06

0:13:06

0:13:07

0:13:07