filmov

tv

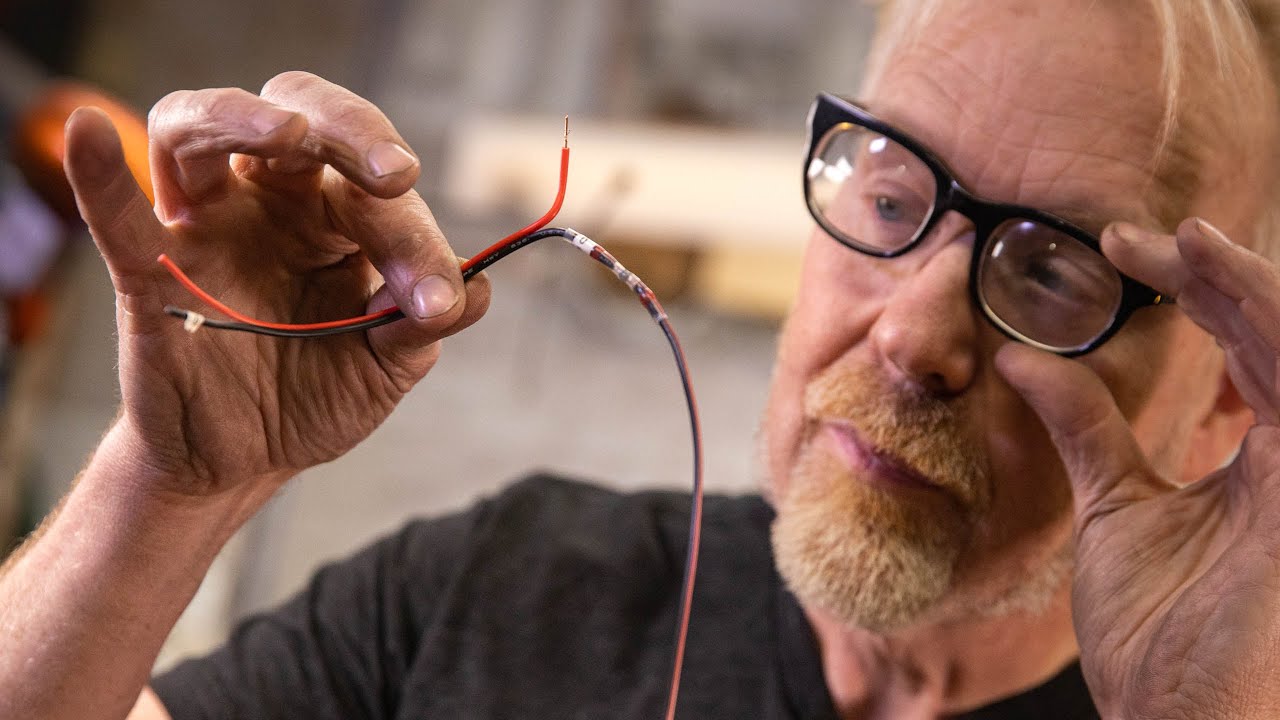

Adam Savage's Quick Electronics Wiring Tips!

Показать описание

Disclaimer: Tested may earn an affiliate commission when you buy through the links here.

Adam introduces two simple tools to help simplify your electronics wiring projects: solder seal connectors that eliminate the need for soldering wires together, and an essential wire labeler that can spare you headaches in troubleshooting down the line. Adam used both of these tools extensively in putting together his xEMU spacesuit electronics--simple and effective is sometimes the best way to go!

Join this channel to support Tested and get access to perks:

Tested is:

Intro bumper by Abe Dieckman

Thanks for watching!

Adam introduces two simple tools to help simplify your electronics wiring projects: solder seal connectors that eliminate the need for soldering wires together, and an essential wire labeler that can spare you headaches in troubleshooting down the line. Adam used both of these tools extensively in putting together his xEMU spacesuit electronics--simple and effective is sometimes the best way to go!

Join this channel to support Tested and get access to perks:

Tested is:

Intro bumper by Abe Dieckman

Thanks for watching!

Комментарии