filmov

tv

How To Splice Wires Like A Pro

Показать описание

Many of our videos are comedic & satirical & not intended to cultivate antisocial or unlawful behavior. Thank you for supporting our Channel through the below affiliate links. No price increase for you but we may receive compensation.

Become A Wranglerstar Member For Exclusive Content and Perks

#Proho #wranglerstar

Become A Wranglerstar Member For Exclusive Content and Perks

#Proho #wranglerstar

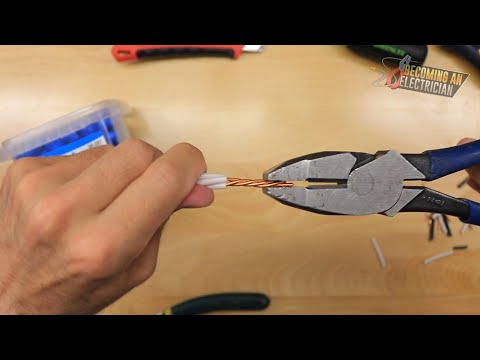

How To Connect or Splice Wires Together - 10 Methods

How to splice wires - how to solder, how to crimp, wire connectors

How To Splice Wires Like A Pro

How to Splice Wires for Electricians

How to Solder Wires Together (Best tips and tricks)

How To Splice Wires to NASA Standards

3 Ways to CORRECTLY Splice Electrical Wires

How to Splice Wires Together in Your Car

LX Dodge Paddle Shifter Install: Part 2 + Tranzformer (05-10 Charger, Challenger, Magnum, 300)

5 CLEVER Electrical Tricks Everyone Should Know

Join wires reliably with NO solder

The Correct Way to T-Splice an Automotive Wire Without Solder

BIGGEST Mistakes DIYers Make When Connecting Wires Together | How To

How to Splice Wires Quickly and Correctly

Splicing Electrical Wire : Western Union Splice (Lineman's Splice)

How to splice a low voltage wire

Wire like a PRO Behind Walls & Fish Electrical Wire / Splice Wires

Never Solder Again - How to Connect Wires the EASY Way

How to Splice Wires - How to Solder and How to Crimp Wire Connectors

Learn How To Splice Wires Like A Pro! #shorts #youtubeshorts

6 Ways to Fix Broken Wires - Beginner Through Pro

How To Splice 3 Wires Together

Must watch!!! How to splice wires together like a pro plus big mistakes to avoid!

How to Splice Electrical Wires Together & Use Heat Shrink Tubing!

Комментарии

0:06:38

0:06:38

0:10:01

0:10:01

0:10:44

0:10:44

0:16:36

0:16:36

0:12:28

0:12:28

0:02:12

0:02:12

0:14:22

0:14:22

0:03:38

0:03:38

0:18:43

0:18:43

0:11:06

0:11:06

0:06:11

0:06:11

0:05:03

0:05:03

0:13:07

0:13:07

0:09:10

0:09:10

0:04:36

0:04:36

0:02:36

0:02:36

0:05:54

0:05:54

0:04:25

0:04:25

0:12:08

0:12:08

0:01:14

0:01:14

0:13:27

0:13:27

0:01:00

0:01:00

0:13:31

0:13:31

0:05:08

0:05:08