filmov

tv

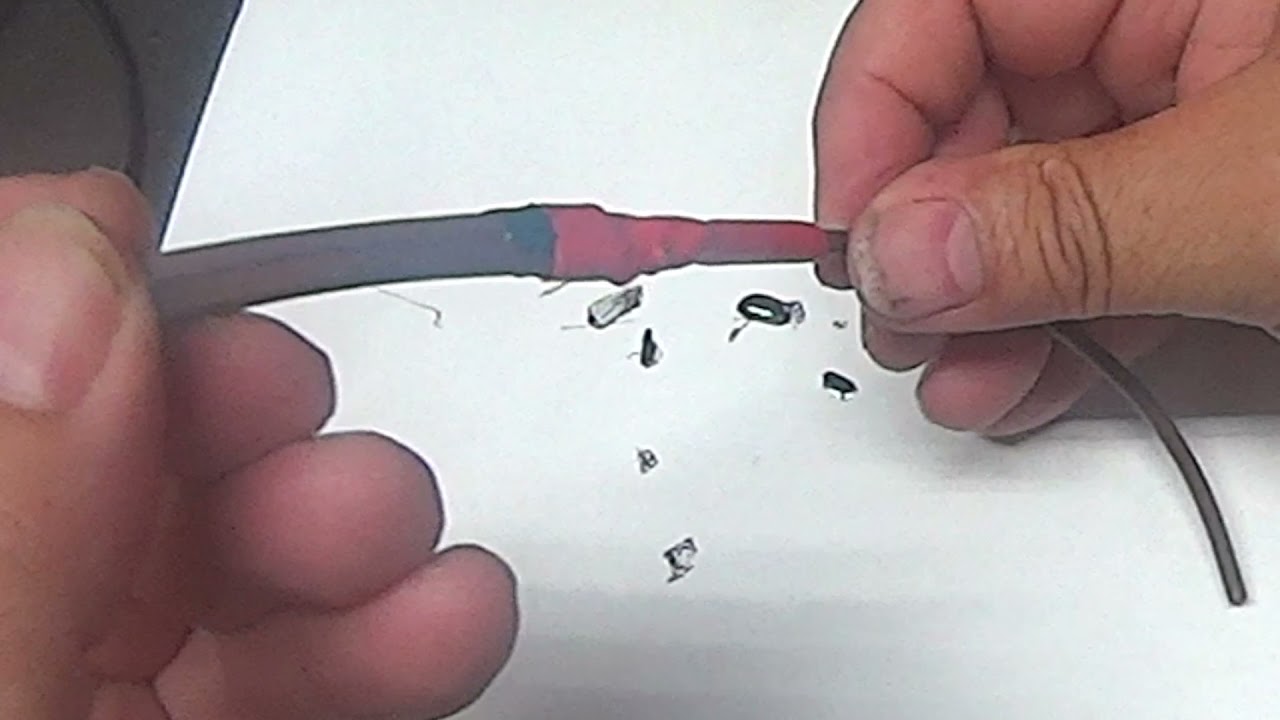

Making waterproof three way splices in RV DC wiring.

Показать описание

This is a follow up to my original video about making waterproof butt-splices (2 way) in a RV's DC system.

In this video, I cover the solder and heat shrink method, plus two commercially available waterproof splices.

---- Advertisement ----

Copyright www.RV-Project.Com

In this video, I cover the solder and heat shrink method, plus two commercially available waterproof splices.

---- Advertisement ----

Copyright www.RV-Project.Com

Making waterproof three way splices in RV DC wiring.

How To Splice Wires: 3 Watertight Methods (Soldered, Solderless, Crimped)

How to Use Quick Splice Connectors & When to Avoid Them

Don't Use Ttap connections instead Military splice and solder the wire connections

How to Use Heat Shrink Butt Splices

Crimpless Butt Connectors - There's A Better Way!

How to tap into a wire without solder or special connectors | Crutchfield

The Correct Way to T-Splice an Automotive Wire Without Solder

How To Splice Wires Properly! Waterproof Wiring Without Solder #Shorts

How to Make Waterproof Wire Splices for Irrigation Systems

Make Your Waterproof Connections The Mess Free Easy Way With WAGO Gel Boxes! #WAGO #Electrician

How to splice wires - how to solder, how to crimp, wire connectors

The best way to splice three wires together

How to Make a Waterproof Splice for Submersible Pumps

Underground splice kit. When done properly its good forever #electrician #splice #construction

Never Solder Again - How to Connect Wires the EASY Way

Waterproof Connections a Step-By-Step Guide (make your own)

Making Waterproof Low Voltage DC Wire Splices in your RV

Making a WAGO CONNECTOR Waterproof 💦

BRILLIANT idea! Proper wire joint 3 way | Perfect Twist Electric Wire Together

How to Properly Join Electrical Wires #shorts #electricaltips #electricalwork #wiring #viral

3 wire pigtail splice

New Wago Electric Connector is SHOCKING everyone - Inline 221 has arrived!

Amazing ways to connect wires

Комментарии

0:07:43

0:07:43

0:05:35

0:05:35

0:02:00

0:02:00

0:01:34

0:01:34

0:00:59

0:00:59

0:00:59

0:00:59

0:02:48

0:02:48

0:05:03

0:05:03

0:00:57

0:00:57

0:04:37

0:04:37

0:00:19

0:00:19

0:10:01

0:10:01

0:05:37

0:05:37

0:19:01

0:19:01

0:00:33

0:00:33

0:04:25

0:04:25

0:07:43

0:07:43

0:07:08

0:07:08

0:00:31

0:00:31

0:02:46

0:02:46

0:00:21

0:00:21

0:00:35

0:00:35

0:04:20

0:04:20

0:00:30

0:00:30