filmov

tv

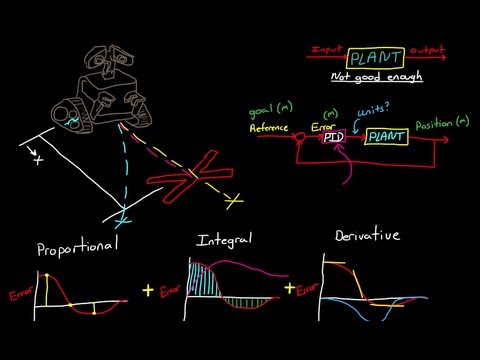

PID controller Simple explanation with a Quadcopter as example.

Показать описание

This video is about a pid controller with a practical example. You will briefly know what a pid controller is and understand the variation of gains in pid loop. The integral gain is crucial in any process*.

Please leave any suggestions in comments.

Resources:

For esp32 flight controller and WiFi pid tuning code.

References:

Please leave any suggestions in comments.

Resources:

For esp32 flight controller and WiFi pid tuning code.

References:

PID Controller Explained

PID controller Simple explanation with a Quadcopter as example.

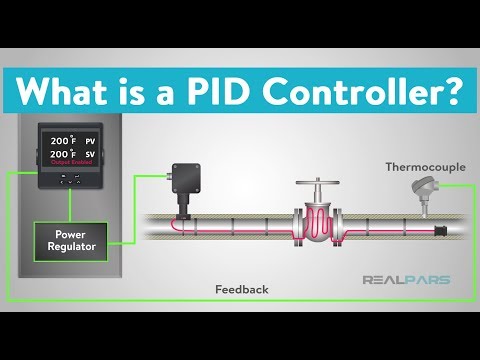

What is a PID Controller?

PID Control - A brief introduction

PIDs Simplified

What is a PID Controller? | DigiKey

What Is PID Control? | Understanding PID Control, Part 1

Simple Examples of PID Control

What is a PID Controller?

PID Controllers made simple!

#182 P, PI, PD, PID controllers || EC Academy

What is PID? The fast explanation

PID Control: The Basics #shorts #thecircuithelper

Introduction to PID Control

How PID Control Works - A Basic PID Introduction

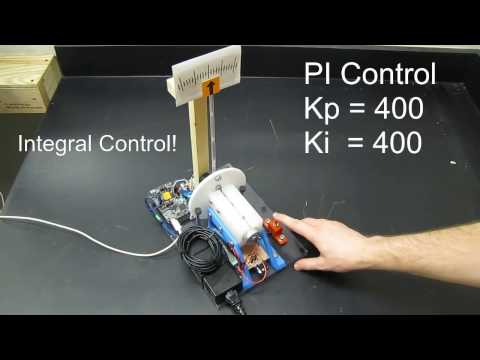

Hardware Demo of a Digital PID Controller

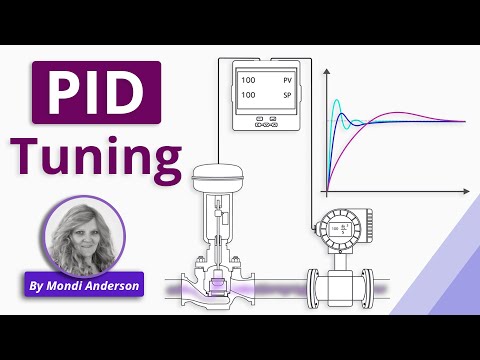

How to Tune a PID Controller

EEVacademy #6 - PID Controllers Explained

Controlling Self Driving Cars

What is a PID controller?

How to Tune a PID Controller - Made Simple!

PID Controller Tuning Easy Method | What are P, I and D terms ?

PID Settings | Proportional-Only Control

PID Balance+Ball | full explanation & tuning

Комментарии

0:09:25

0:09:25

0:21:28

0:21:28

0:05:39

0:05:39

0:07:44

0:07:44

0:13:07

0:13:07

0:22:19

0:22:19

0:11:42

0:11:42

0:13:10

0:13:10

0:11:32

0:11:32

0:10:02

0:10:02

0:04:51

0:04:51

0:02:20

0:02:20

0:00:46

0:00:46

0:49:18

0:49:18

0:14:13

0:14:13

0:02:58

0:02:58

0:08:43

0:08:43

0:27:11

0:27:11

0:04:41

0:04:41

0:03:28

0:03:28

0:14:34

0:14:34

0:05:16

0:05:16

0:08:10

0:08:10

0:13:13

0:13:13