filmov

tv

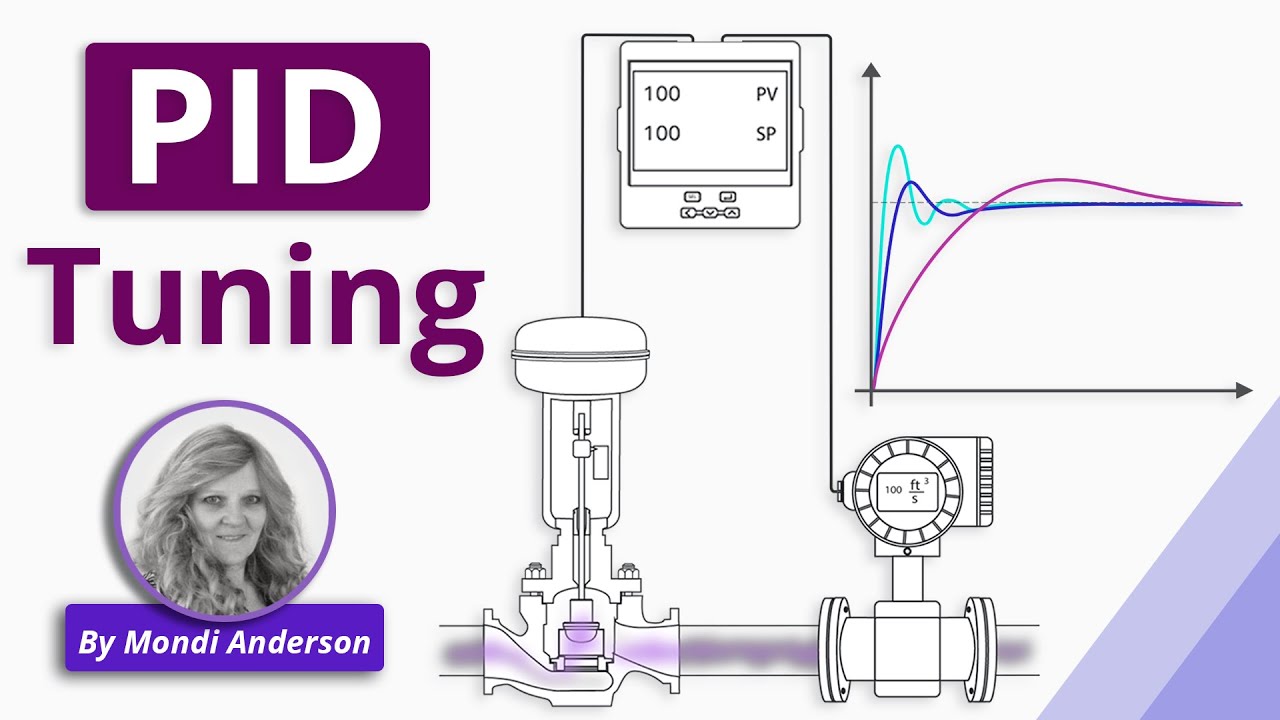

How to Tune a PID Controller

Показать описание

▶ Check out the full blog post over at

=============================

⌚Timestamps:

00:00 - Intro

01:06 - Proportional term

02:04 - Integral term

03:06 - Derivative term

03:54 - Algorithms and parameters

04:44 - PID tuning methods

05:59 - Tune a PI controller

=============================

let’s discuss what the PID parameters are and how they are used.

In the most simplistic terms, the controller calculates the P, I, and D actions and multiplies each parameter by the error or E, which is equal to SP-PV indirect-acting, as discussed previously.

Then, all parameter calculations are added up to produce the Control Variable.

1) The proportional term, often called P Constant, can be referred to as Proportional Gain or just Gain, which is not a unit but instead a ratio.

For controllers that use the term Gain, adjusting this tuning parameter higher may cause more sensitive, less stable loops.

Conversely, on controllers with proportional band units, decreasing this tuning parameter affects the loop in the same manner.

2) The Integral term or I Constant, often called Reset, can be expressed differently as well such as repeats per second, seconds per repeat, repeats per minute, and minutes per repeat.

Essentially, regardless of the measurement type, the integral is the sum of all of the values reported from the signal, captured from when you started counting to when you completed counting or the area under a plotted curve.

This parameter can be called Ki, Ti, or others. This parameter determines how fast the steady-state error is removed.

3) Derivative or D Constant units are typically seconds or minutes.

The purpose of the Derivative constant is for predicting change. The Derivative action acts of the rate of change measured in the Process Variable.

The value of this parameter basically means how far in the future you want to predict the rate of change. This parameter can help to create a faster response in your loop and a better performing loop as well.

The most commonly used controller is the PI. Most processes can be well served with this type of control. P and PID controllers are occasionally used while PD controllers are rarely used.

PID controllers are very sophisticated devices with likely many adjustable parameters. The process and algorithm types can also vary.

Other parameters to research for PID controllers are Series, Ideal, and Parallel algorithms, filtering, scan times, anti-windup, self-regulating versus integrating processes, reverse acting, dead time, lag, Derivative on E or Derivative on PV, just to mention a few.

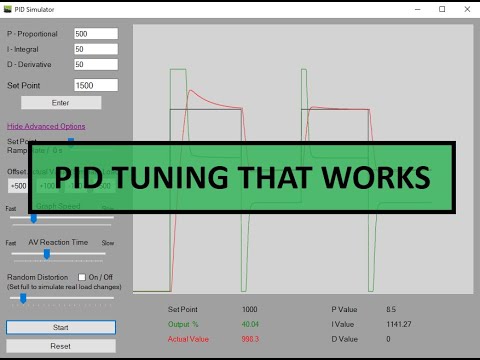

There is a science to tuning a PID loop but the most widely used tuning method is trial and error. There are other methods that require a multistep process to determine where your numbers should be. The goal of tuning is to ensure minimal process oscillation around the setpoint after a disturbance has occurred.

The first step in tuning your controller is to determine just how much adjustment you can make without serious implications to the process.

Talk to the plant personnel, if adjusting the parameters of the PID controller will not have an adverse reaction then you can begin your adjustments. If the effects will be detrimental, you must take a more measured approach.

=============================

You might want to review our previous articles:

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos and more lessons, make sure to subscribe to this YouTube channel:

=============================

=============================

#RealPars #PID #IndustrialAutomation

Комментарии

0:08:43

0:08:43

0:18:14

0:18:14

0:07:08

0:07:08

0:14:34

0:14:34

0:13:07

0:13:07

0:09:25

0:09:25

0:16:57

0:16:57

0:13:31

0:13:31

0:21:51

0:21:51

0:06:19

0:06:19

0:05:16

0:05:16

0:00:16

0:00:16

0:24:50

0:24:50

0:02:05

0:02:05

0:06:01

0:06:01

0:12:32

0:12:32

0:02:50

0:02:50

0:02:11

0:02:11

0:08:54

0:08:54

0:33:39

0:33:39

0:43:49

0:43:49

0:00:21

0:00:21

0:02:36

0:02:36

0:13:13

0:13:13