filmov

tv

7018 Open Root Challenge

Показать описание

#welddotcom

It's his first first time welding 7018 open root.

No research.

No advice.

Just a little prayer to the welding gods...

You can join our groups and forums, ask technical questions, answer questions in the community, look for jobs and more!

Don't miss new episodes of our podcast, please subscribe and leave us a review!

Now available on these platforms:

Brands that Support the Channel:

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

It's his first first time welding 7018 open root.

No research.

No advice.

Just a little prayer to the welding gods...

You can join our groups and forums, ask technical questions, answer questions in the community, look for jobs and more!

Don't miss new episodes of our podcast, please subscribe and leave us a review!

Now available on these platforms:

Brands that Support the Channel:

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

7018 Open Root Challenge

7016 Stick Welding Open Root

How To Weld: Weaving On Pipe With A 7018 Rod

weding root pass#7018(3.2 mm)pipe welding#company #ofwlife #subscribetomychannel #company

Crazy Welding Skills on Display at WorldSkills 2022 Special Edition

3/8' Plate Test 3G | Stick Welding

🔥 6g Pipe Welding: 6010 Root 7018 Fill and Cap

7016 3G Open Root Pass

🔥 Downhill Open Root 6010 with UNEVEN FITUP

Open Root Weld 3G position

1/8 6010 3g open root

Open Root 6010 Tips and Tricks | Live from Fabtech 2022

[WELD TESTING] ANOTHER UNEXPECTED TEST!... NEVER TOOK THAT BEFORE?

RazorWeld 110 Overview: Part 1 - Stick Welding with 6011 and 7018 | TIG Time

2 Tips in 2 Minutes to Better 7018 Welds

3g welding|welding test3g 7018|Root welding method|3g secret

Almost 3 Years As A condo Owner in Miami Beach.. This is pretty normal on a Monday in South Beach

6010 5/32' Open Root Practice

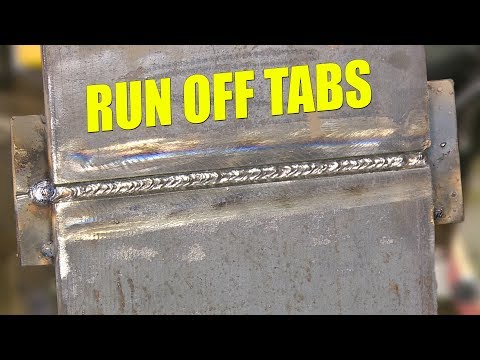

🔥 2G SMAW with Run Off Tabs

Extreme DIY Challenge: Torch Your Nuts in Pipe Welding!

7018 5/32' Overhead Welding

Dual Shield Flux Core and 7018 Stick Welding Uphill

Get Better At Tig Root Welding With These Tips And Tricks!

Stick Welding: How to Read the Puddle

Комментарии

0:09:17

0:09:17

0:08:03

0:08:03

0:08:24

0:08:24

0:00:13

0:00:13

0:12:58

0:12:58

0:17:54

0:17:54

0:19:54

0:19:54

0:03:49

0:03:49

0:07:33

0:07:33

0:13:01

0:13:01

0:00:51

0:00:51

0:09:17

0:09:17

![[WELD TESTING] ANOTHER](https://i.ytimg.com/vi/FASCssIYykg/hqdefault.jpg) 0:15:59

0:15:59

0:09:49

0:09:49

0:05:07

0:05:07

0:16:40

0:16:40

0:00:26

0:00:26

0:06:28

0:06:28

0:09:27

0:09:27

0:00:52

0:00:52

0:06:36

0:06:36

0:10:37

0:10:37

0:10:06

0:10:06

0:06:06

0:06:06