filmov

tv

Basic Plumbing: Copper Pipe Prep 💪🏼💰🔥💯

Показать описание

Removal of the burr/ridge formed when cutting copper is critical. Thru time water (or any fluid in the pipe) will wear thru the pipe if the ridge is not removed.

This is the most basic of copper plumbing. Yet so many skip this important step.

This is the most basic of copper plumbing. Yet so many skip this important step.

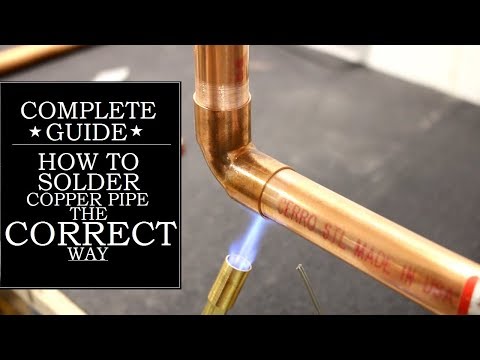

How To Solder Copper Pipe (Complete Guide) Plumbing 101

Basic Plumbing: Copper Pipe Prep 💪🏼💰🔥💯

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

How To Solder Copper Pipes Like A Pro

How To Solder Copper Pipe Like a Pro (Tips & Tricks) | GOT2LEARN

How to CORRECTLY Solder A Vertical Copper Pipe (Complete Guide) | GOT2LEARN

Solder Vertical Copper Pipes for Beginners

6 SOLDERING MISTAKES ON COPPER PIPE

How to ProPress Copper Pipes (Pros & Cons) | GOT2LEARN

How to use a compression fitting. Compression plumbing tutorial. Plumbing for beginners!

Copper Pipe Soldering Tips - #shorts

Plumbing basics: Soldering copper into an old fitting #plumbing #hvac #heating

Mistakes Apprentice Plumbers ALWAYS Make When Soldering

How to solder a hole in a copper pipe. Plumber's Tricks. DIY

How to Join Plastic and Copper Pipes | Plumbing Guide for Beginners

How To CORRECTLY Solder a 2' Copper Joint (Step By Step) | GOT2LEARN

5 MISTAKES Beginners Make When Soldering Copper Pipe | GOT2LEARN

How to prepare and solder copper pipes and fittings.

4 MISTAKES Everyone Makes When Using COMPRESSION FITTINGS

How to install a COMPRESSION fitting! | GOT2LEARN

How To Solder Copper Pipes | The Home Depot with @thisoldhouse

Measure a 45 Offset | Advanced Plumbing

Compression Fitting 101: Everything You Need to Know

Solder Copper Pipe like a Pro (Tips and Tricks) Pt 2. #shorts #plumbing #soldering

Комментарии

0:05:54

0:05:54

0:01:00

0:01:00

0:05:05

0:05:05

0:11:56

0:11:56

0:10:46

0:10:46

0:13:48

0:13:48

0:03:22

0:03:22

0:11:49

0:11:49

0:11:02

0:11:02

0:02:37

0:02:37

0:00:19

0:00:19

0:01:01

0:01:01

0:08:46

0:08:46

0:02:35

0:02:35

0:11:52

0:11:52

0:06:36

0:06:36

0:06:05

0:06:05

0:05:16

0:05:16

0:10:49

0:10:49

0:02:50

0:02:50

0:03:57

0:03:57

0:11:50

0:11:50

0:06:06

0:06:06

0:00:41

0:00:41