filmov

tv

6 SOLDERING MISTAKES ON COPPER PIPE

Показать описание

6 SOLDERING MISTAKES ON COPPER PIPE

----

Don't make these 4 soldering mistakes that LOADS of people make when working on copper pipe!

TimeStamps:

00:00 Intro

00:18 Not making sure the copper pipe is clean

01:40 Not using flux on the copper pipe

02:50 Clean the inside of the fitting

03:38 AN EXTRA PLUMBING TIP

03:52 What too much heat does to your copper pipe solder

05:12 What too little heat does to your solder job

06:10 Useing the right amount of solder on the copper fitting

08:35 ANOTHER EXTRA PLUMBING TIP

09:10 Trying to solder when water is in the pipe

11:30 ONE FINAL PLUMBING TIP 😉

-----

------

-------

----

Don't make these 4 soldering mistakes that LOADS of people make when working on copper pipe!

TimeStamps:

00:00 Intro

00:18 Not making sure the copper pipe is clean

01:40 Not using flux on the copper pipe

02:50 Clean the inside of the fitting

03:38 AN EXTRA PLUMBING TIP

03:52 What too much heat does to your copper pipe solder

05:12 What too little heat does to your solder job

06:10 Useing the right amount of solder on the copper fitting

08:35 ANOTHER EXTRA PLUMBING TIP

09:10 Trying to solder when water is in the pipe

11:30 ONE FINAL PLUMBING TIP 😉

-----

------

-------

6 SOLDERING MISTAKES ON COPPER PIPE

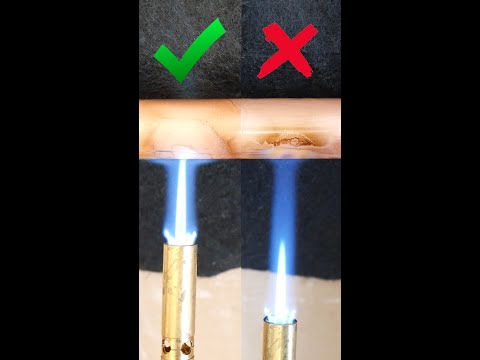

SOLDERING MISTAKE #6 (flame position)

SOLDERING MISTAKE #2 (heat quantity)

How to Solder Copper

Common Soldering Mistakes | Soldering

HOW TO SOLDER COPPER PIPE | Real World Plumbing #howto #plumbing #asmr

SOLDERING MISTAKE #5 (heating location)

How To Solder Copper Pipes Like A Pro #diy #shorts

The WORST Mistake When Soldering Copper Pipe (Not Deburring) | GOT2LEARN

6 SHARKBITE Mistakes NOT To Make! | GOT2LEARN

5 MISTAKES Beginners Make When Soldering Copper Pipe | GOT2LEARN

SOLDERING MISTAKE #3 (unclean surfaces)

How I solder a joint VERTICALLY and why | GOT2LEARN

Copper Pipe Soldering Tips - #shorts

How to solder copper pipe. #shorts #youtubeshorts #diy

How to Braze Copper Plumbing Lines

SOLDERING MISTAKE #1 (Flux quantity)

Soldering 1-1/2' Copper Pipe #shorts

SOLDERING MISTAKE #4

Watch me ROAST a Solder Joint!

Desoldering | Soldering Basics | Soldering for Beginners

The correct way to use tin soldering iron.

How to Repair Broken or Torn Flex , Flexible Cables #shorts

How to solder a LEAD-FREE ball valve | GOT2LEARN

Комментарии

0:11:49

0:11:49

0:00:52

0:00:52

0:01:00

0:01:00

0:00:41

0:00:41

0:03:15

0:03:15

0:00:34

0:00:34

0:00:45

0:00:45

0:00:20

0:00:20

0:07:32

0:07:32

0:04:16

0:04:16

0:06:05

0:06:05

0:00:44

0:00:44

0:01:00

0:01:00

0:00:37

0:00:37

0:00:23

0:00:23

0:00:29

0:00:29

0:00:57

0:00:57

0:00:20

0:00:20

0:01:00

0:01:00

0:00:35

0:00:35

0:03:20

0:03:20

0:00:17

0:00:17

0:00:26

0:00:26

0:00:59

0:00:59