filmov

tv

How to solder a hole in a copper pipe. Plumber's Tricks. DIY

Показать описание

Plumber's Tricks.DIY. How to solder a hole in a copper pipe with your own hands.

How to Solder properly || Through-hole (THT) & Surface-mount (SMD)

How to Solder Through-Hole Components - Another Teaching Moment | DigiKey Electronics

SDG #066 Solder Through-hole Components - Soldering Techniques #02

Car Body Sheet Metal Repair With Solder. No Welder Needed.

How to solder a hole in a copper pipe. Plumber's Tricks. DIY

How to Solder Through Hole Components | Hardware & Electronics: 02

Learn How to Solder - 102 Level - Through Hole Component Soldering for Electronics and Game Consoles

Body Solder of Pinholes

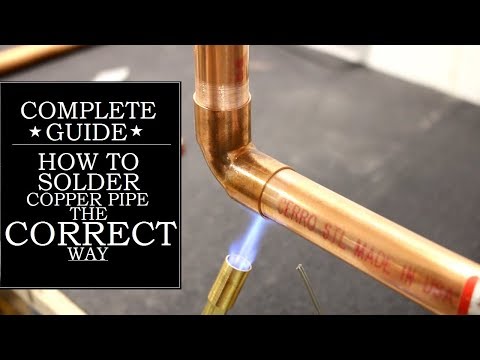

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

How To Solder Holes In Motorcycle Gas Tanks (2019)

Beginner how to Solder

Voltlog #179 - How To Solder Through-Hole Parts

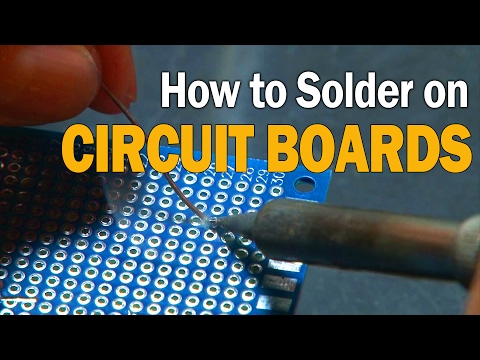

How to Solder on Circuit Boards!

HOW TO SOLDER! (Beginner's Guide)

Can You Temporarily PATCH a Pinhole With Solder? | GOT2LEARN

The easy way to solder through hole parts

How To Solder - Through Hole Soldering Guide

Soldering tips and tricks - Tip5 Don't try to solder a wire when flux from solder was evapora...

Tips of the Trade: Clearing Solder out of a Through Hole

How to Solder Surface Mount Components | Soldering

How to Solder Through-hole Capacitors onto a PCB!

HOW TO SOLDER

How to Solder a Wire to a Circuit Board

How to solder - Through Hole Components (THC)

Комментарии

0:11:08

0:11:08

0:03:47

0:03:47

0:04:50

0:04:50

0:03:40

0:03:40

0:02:35

0:02:35

0:13:04

0:13:04

0:09:10

0:09:10

0:03:55

0:03:55

0:05:05

0:05:05

0:03:14

0:03:14

0:06:29

0:06:29

0:12:53

0:12:53

0:03:51

0:03:51

0:22:03

0:22:03

0:02:03

0:02:03

0:02:08

0:02:08

0:10:54

0:10:54

0:00:47

0:00:47

0:03:54

0:03:54

0:01:32

0:01:32

0:00:16

0:00:16

0:09:51

0:09:51

0:01:24

0:01:24

0:04:55

0:04:55