filmov

tv

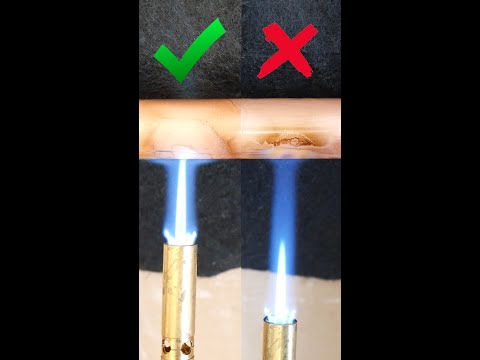

Mistakes Apprentice Plumbers ALWAYS Make When Soldering

Показать описание

Soldering copper pipe is VERY common in plumbing. During your plumbing apprenticeship you'll have to learn about soldering. Soldering scares a lot of plumbers, but it really shouldn't. With a little practice, learning to solder copper pipe become very easy very quickly. In this video I'm going to tell you some of the common mistakes apprentice plumbers make when learning to solder. Hopefully this helps you in your plumbing career!

Thanks for watching! I'm Roger Wakefield, LEED AP, The Expert Plumber and welcome to my channel. On this channel I teach homeowners how to save money on their plumbing by doing DIY plumbing projects. I also teach plumbers and plumbing company owners how to be the best plumbers in their area and run successful plumbing businesses. My goal is teach you everything you need to know about plumbing.

► Check Out Our Social Media:

► Gear We Use:

*NOTE: This description contains affiliate links that allow you to find the items mentioned in this video and support the channel at NO COST TO YOU. While this channel may earn minimal sums when the viewer uses the links, the viewer is in NO WAY obligated to use these links. Thank you for your support!

Thanks for watching! I'm Roger Wakefield, LEED AP, The Expert Plumber and welcome to my channel. On this channel I teach homeowners how to save money on their plumbing by doing DIY plumbing projects. I also teach plumbers and plumbing company owners how to be the best plumbers in their area and run successful plumbing businesses. My goal is teach you everything you need to know about plumbing.

► Check Out Our Social Media:

► Gear We Use:

*NOTE: This description contains affiliate links that allow you to find the items mentioned in this video and support the channel at NO COST TO YOU. While this channel may earn minimal sums when the viewer uses the links, the viewer is in NO WAY obligated to use these links. Thank you for your support!

Комментарии

0:08:46

0:08:46

0:10:31

0:10:31

0:18:24

0:18:24

0:18:43

0:18:43

0:12:12

0:12:12

0:08:32

0:08:32

0:00:52

0:00:52

0:00:56

0:00:56

0:07:36

0:07:36

0:08:19

0:08:19

0:00:12

0:00:12

0:01:00

0:01:00

0:00:15

0:00:15

0:00:10

0:00:10

0:05:58

0:05:58

0:09:03

0:09:03

0:06:44

0:06:44

0:05:08

0:05:08

0:10:01

0:10:01

0:00:55

0:00:55

0:18:56

0:18:56

0:09:35

0:09:35

0:01:01

0:01:01

0:09:38

0:09:38