filmov

tv

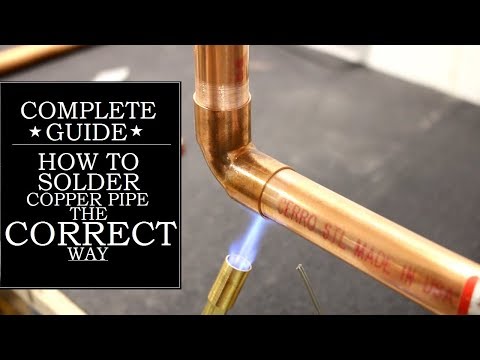

How To Solder Copper Pipes Like A Pro

Показать описание

Roger shows us how to solder copper pipework like a pro.

Fluxuator Dual Head Flux Applicator 15mm & 22mm

Pipestation Map Plus Pro Blow Torch

LA-CO Cool Gel Heat Barrier Spray

SPRAYZ Large 500ml Spray Bottle

___________________________________

Check out James @plumberparts

Plumberparts Amazon Shop

00:00 Preparation

01:54 Applying flux

02:56 Cleaning pipe

03:42 Soldering fitting

04:12 End feed fitting

05:17 Fluxuator

06:16 Heat matt

07:04 Pipe clips

07:47 Blow lamp

08:06 How much solder?

08:52 Soldering

10:23 Final thoughts

==============================

#solder #soldering #plumbing

🛒 As an Amazon Associate, we earn from qualifying purchases

◾ Out of respect to our channel sponsors and the wide variety of people who watch our videos, we'll remove comments that do not follow common standards of politeness and decency.

✅ ▶ ⏩ 🔘 ⚫

Fluxuator Dual Head Flux Applicator 15mm & 22mm

Pipestation Map Plus Pro Blow Torch

LA-CO Cool Gel Heat Barrier Spray

SPRAYZ Large 500ml Spray Bottle

___________________________________

Check out James @plumberparts

Plumberparts Amazon Shop

00:00 Preparation

01:54 Applying flux

02:56 Cleaning pipe

03:42 Soldering fitting

04:12 End feed fitting

05:17 Fluxuator

06:16 Heat matt

07:04 Pipe clips

07:47 Blow lamp

08:06 How much solder?

08:52 Soldering

10:23 Final thoughts

==============================

#solder #soldering #plumbing

🛒 As an Amazon Associate, we earn from qualifying purchases

◾ Out of respect to our channel sponsors and the wide variety of people who watch our videos, we'll remove comments that do not follow common standards of politeness and decency.

✅ ▶ ⏩ 🔘 ⚫

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

How To Solder Copper Pipe (Complete Guide) Plumbing 101

How To Solder Copper Pipes Like A Pro

How To Solder Copper Pipe Like a Pro (Tips & Tricks) | GOT2LEARN

Solder Vertical Copper Pipes for Beginners

How to CORRECTLY Solder A Vertical Copper Pipe (Complete Guide) | GOT2LEARN

How To Solder Copper Pipes | The Home Depot with @thisoldhouse

6 SOLDERING MISTAKES ON COPPER PIPE

How to Solder a Pipe | Ask Richard | Ask This Old House

Copper Pipe Soldering Tips - #shorts

How to solder / sweat copper pipe for beginners in 7 easy steps

How To Solder Copper Pipe In Tight Spaces (How To Solder Copper Pipe Like A Pro) Plumbing 101

UNMISSABLE TIP How To Solder Copper Pipe Without Runs

How to solder copper, secret soldering and how not to solder

How to Solder Copper Pipe in a Wall (Complete Guide) | GOT2LEARN

How to Solder Yorkshire Fittings | Solder Ring fittings | Capillary Fittings

7 STEPS TO SOLDER COPPER PIPE

Insane Plumber's Trick: Solder Copper Pipes Dripping Water

The CORRECT Way To Fix A Leaking Joint (UNSOLDERING) | GOT2LEARN

Soldering Copper Pipes With Water in Them (7 Solutions) | GOT2LEARN

How to Solder Copper Pipe (Important Tips!!) -- by Home Repair Tutor

How To Solder Copper Pipe Between 2 Studs With No Movement | GOT2LEARN

Mistakes Apprentice Plumbers ALWAYS Make When Soldering

5 MISTAKES Beginners Make When Soldering Copper Pipe | GOT2LEARN

Комментарии

0:05:05

0:05:05

0:05:54

0:05:54

0:11:56

0:11:56

0:10:46

0:10:46

0:03:22

0:03:22

0:13:48

0:13:48

0:03:57

0:03:57

0:11:49

0:11:49

0:01:53

0:01:53

0:00:19

0:00:19

0:04:13

0:04:13

0:09:32

0:09:32

0:08:26

0:08:26

0:15:04

0:15:04

0:15:30

0:15:30

0:11:03

0:11:03

0:11:06

0:11:06

0:07:05

0:07:05

0:10:38

0:10:38

0:06:05

0:06:05

0:09:46

0:09:46

0:04:31

0:04:31

0:08:46

0:08:46

0:06:05

0:06:05