filmov

tv

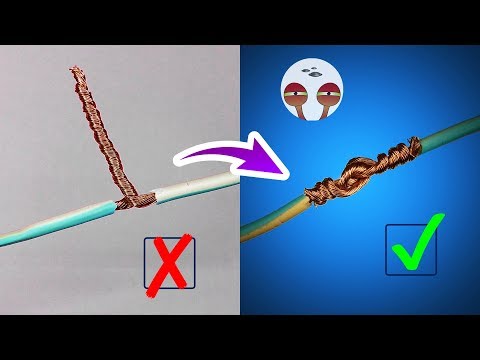

Join wires reliably with NO solder

Показать описание

A quick tech tip to let you in on this technique for joining two wires together. The advantages of this over crimping or soldering are speed, reliability, and flexibility.

Welcome to Tech Tip Tuesday! Our tech tip videos teach you technical skills for working on your car. Our goal is to create a resource of educational information specifically for working on older cars, classic cars, and weird cars. Subscribe for more!

Welcome to Tech Tip Tuesday! Our tech tip videos teach you technical skills for working on your car. Our goal is to create a resource of educational information specifically for working on older cars, classic cars, and weird cars. Subscribe for more!

Комментарии