filmov

tv

50 3D Modeling Tips and Best Practices for Mechanical Designs. - Jeremy Fielding 099

Показать описание

You can register for 3D Experience World 2022 virtual event for

@solidworks

#3DXW22

#SOLIDWORKS

#3DMODELING

If you want to chip in a few bucks to support these projects and teaching videos, please visit my Patreon page or Buy Me a Coffee.

Social media

Fatherhood engineered channel

************************************

Notes:

First video in the series 18 mechanical design tips and tricks

Technical corrections

Nothing yet

@solidworks

#3DXW22

#SOLIDWORKS

#3DMODELING

If you want to chip in a few bucks to support these projects and teaching videos, please visit my Patreon page or Buy Me a Coffee.

Social media

Fatherhood engineered channel

************************************

Notes:

First video in the series 18 mechanical design tips and tricks

Technical corrections

Nothing yet

50 3D Modeling Tips and Best Practices for Mechanical Designs. - Jeremy Fielding 099

50+ Blender Tips and Tricks (that you'll actually use!)

I packed 50 BLENDER TIPS into one video!

Master Autodesk Inventor: Detailed Part Modeling Tutorial | Example 50

50 3D Printing Tips and Tricks eBook

100+ Tips to Boost Modeling in Blender

5 must-know 3D printing tips & tricks. (stronger and better looking prints)

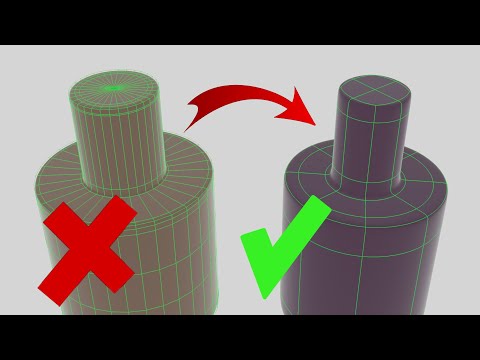

7 Topology Tips Every 3D Artist Should Know

Model and Render a Realistic Perfume Bottle in Blender – Beginner's Guide!

3D Models That Will END Your Career

My 50 Favorite Blender Tips & Tricks! | Quick Tip Compilation

Five Topology Tips Every 3D Artist Should Know

5 Advanced 3D Modelling Tips for COMPLEX 3D Printed Models

All 54 Modifiers in Blender Explained in 10 Minutes

The ONLY 5 Modeling Tools You Need To Make ANYTHING in Blender

50+ Useful 3D Prints You Never Knew You Could Print

10 Tools Every Blender Noob Should Learn

3 Design Tips for Better 3D Printed Holes - CAD For Newbies

10 Secret 3D Printing Tricks Only Experts Know...

15 Blender Tips To Improve Your Workflow

FAST Modelling - 5 Secrets You Need To Know!

If I Started Blender In 2024, I'd Do This

Must Have 3D Printing Tips and Tricks! Episode 1 - Design Stage

Let's Learn Blender! #4: 3D Modelling in Edit Mode!: Part 1

Комментарии

0:37:57

0:37:57

0:10:53

0:10:53

0:32:26

0:32:26

0:08:19

0:08:19

0:04:01

0:04:01

1:57:05

1:57:05

0:02:44

0:02:44

0:09:27

0:09:27

1:36:42

1:36:42

0:11:29

0:11:29

0:18:10

0:18:10

0:13:17

0:13:17

0:15:04

0:15:04

0:11:31

0:11:31

0:07:13

0:07:13

0:24:02

0:24:02

0:09:44

0:09:44

0:07:23

0:07:23

0:04:35

0:04:35

0:05:45

0:05:45

0:05:48

0:05:48

0:10:51

0:10:51

0:07:52

0:07:52

0:51:55

0:51:55