filmov

tv

10 Secret 3D Printing Tricks Only Experts Know...

Показать описание

"As a engineer who has been 3D printing for 7 years these are some amazing tips. I wish I had when I was first getting started and that chain idea is actually new to me and glad I watched!" - Mathew Gonzalez • (April 2023)

Happy printing!

-Steven

_____

Favorite printer: @BambuLab X1 Carbon

Favorite filament: Bambu Lab filament

______ music:

Happy printing!

-Steven

_____

Favorite printer: @BambuLab X1 Carbon

Favorite filament: Bambu Lab filament

______ music:

10 Secret 3D Printing Tricks Only Experts Know...

5 must-know 3D printing tips & tricks. (stronger and better looking prints)

5 3D Printing Tips the ELITES don't want you to know... #3DP101

My Secret To No More 3D Printed Layer Lines

50+ Useful 3D Prints You Never Knew You Could Print

printed WITHOUT support #shorts

Stop 3d printing so slow!!! 🤯 (how to print faster)

The Ultimate Guide to Perfect 3D Prints

Creality Ender 3 V2 - Simple Tips for Super Clean 3D Prints

15 Useful 3D Prints: Go From Beginner to Advanced!

The secret to 3D printing PETG [Adventurer 4]

Did pencils really need to evolve like this?? #amazon #amazonfinds #amazonhome #amazonlife

Top 10 3D Printing Tips THAT WILL CHANGE YOUR LIFE! ( April Fools 2023)

Top 10 3D Printable Tools Every Maker Should, Like, Make

5 Practical 3D Printing Tips

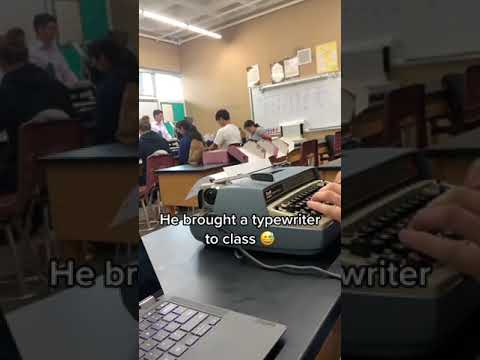

His laptop died so he used his TYPEWRITER. 😭🤷♂️ #shorts

What Does a 4D Ball Look Like in Real Life? Amazing Experiment Shows Spherical Version of Tesseract

An interesting EDC Altoids tin modification

Conical Slicing: A different angle of 3D printing

Cardboard weapon showcase

these glasses help you do ONE thing

My Weirdest Rubik’s cubes #shorts

How Drone insect was CAUGHT Spying on Africa #shorts #youtubeshorts

15 Tips in 15 Minutes: Quick & Easy 3D Printing Tips

Комментарии

0:04:35

0:04:35

0:02:44

0:02:44

0:07:26

0:07:26

0:10:36

0:10:36

0:24:02

0:24:02

0:01:00

0:01:00

0:04:14

0:04:14

0:17:27

0:17:27

0:08:26

0:08:26

0:18:52

0:18:52

0:13:45

0:13:45

0:00:22

0:00:22

0:09:15

0:09:15

0:09:49

0:09:49

0:01:00

0:01:00

0:00:42

0:00:42

0:07:52

0:07:52

0:00:29

0:00:29

0:14:51

0:14:51

0:00:15

0:00:15

0:00:24

0:00:24

0:00:19

0:00:19

0:00:31

0:00:31

0:15:06

0:15:06