filmov

tv

EEVblog #532 - Silicon Chip Wafer Fab Mailbag

Показать описание

A look at some equipment and wafers used in the manufacture of silicon chip wafers.

200mm and 300mm wafers, die, dice sawing, lead-frame manufacture, automated testing machine (ATE) probing, clean room bunnie suits, photo plots, BGA chip thermal test sockets, and the worlds smallest active FET probes at 100 nanometers for direct wafer probing!

Thanks to Vincent Himpe:

EEVblog Main Web Site:

EEVblog Amazon Store:

Donations:

Projects:

Electronics Info Wiki:

200mm and 300mm wafers, die, dice sawing, lead-frame manufacture, automated testing machine (ATE) probing, clean room bunnie suits, photo plots, BGA chip thermal test sockets, and the worlds smallest active FET probes at 100 nanometers for direct wafer probing!

Thanks to Vincent Himpe:

EEVblog Main Web Site:

EEVblog Amazon Store:

Donations:

Projects:

Electronics Info Wiki:

EEVblog #532 - Silicon Chip Wafer Fab Mailbag

EEVblog #663 - Compucorp 322G Calculator Teardown

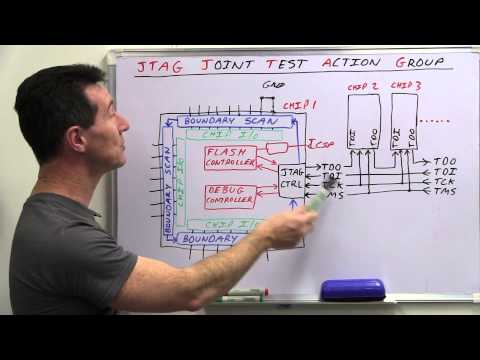

EEVblog #499 - What is JTAG and Boundary Scan?

EEVblog #1034 - Mailbag

EEVblog #553 - Mailbag

EEVblog #239 - PCB Design For Manufacture Part 2

EEVblog #1003 - Mailbag

EEVblog #446 - Dumpster Diving Samsung Plasma TV

EEVblog #513 - Mailbag

EEVblog #437 - Removing SMD Parts with ChipQuik

EEVblog #1043 - Mailbag

EEVblog #462 - Video Editing PC Assembly

EEVblog #545 - Vintage Design Rant

EEVblog #1180 - Component Parametric Search Tutorial

EEVblog #954 - How To Setup An Electronics Lab For $300

EEVblog #773 - 80W INDUAL LED Light Teardown

EEVblog #138 - Top 5 Tips for Graduate Engineers

EEVblog #1189 - Ebay $140 6.5 digit DMM Bargain!?

EEVblog #359 - QDSO Pocket Oscilloscope Review

EEVblog #481 - Mailbag

EEVBlog 1436 - The TOP 5 Jellybean OPAMP's

EEVblog #1244 - Mailbag

EEVblog #447 - Samsung Plasma Followup

EEVblog #168 - How To Set Up An Electronics Lab

Комментарии

0:41:36

0:41:36

0:29:18

0:29:18

0:28:59

0:28:59

0:42:04

0:42:04

0:25:56

0:25:56

0:56:54

0:56:54

0:43:49

0:43:49

0:34:16

0:34:16

0:32:21

0:32:21

0:20:47

0:20:47

0:45:51

0:45:51

0:59:27

0:59:27

0:04:04

0:04:04

0:35:53

0:35:53

0:12:24

0:12:24

0:25:51

0:25:51

0:11:45

0:11:45

0:28:41

0:28:41

0:33:14

0:33:14

0:40:53

0:40:53

0:27:14

0:27:14

0:49:54

0:49:54

0:15:24

0:15:24

0:27:09

0:27:09