filmov

tv

EEVblog #239 - PCB Design For Manufacture Part 2

Показать описание

A follow up to Dave's popular PCB Design For Manufacture (DFM) tutorial video.

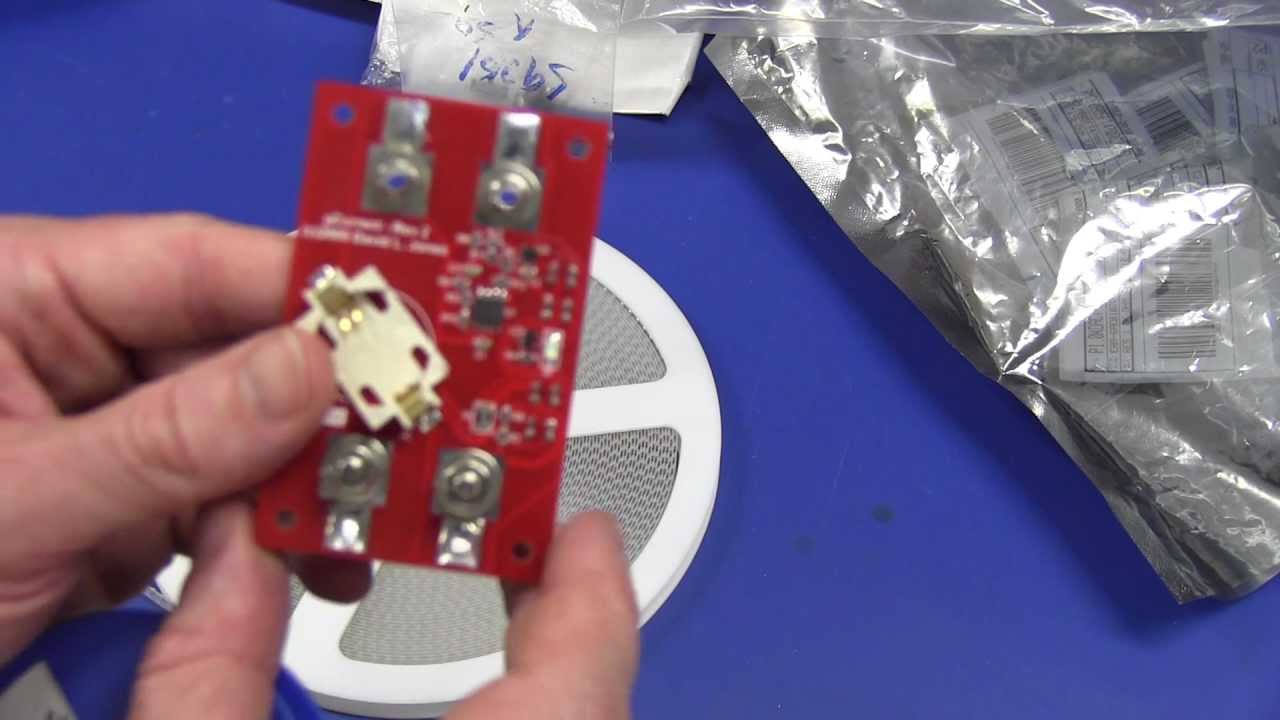

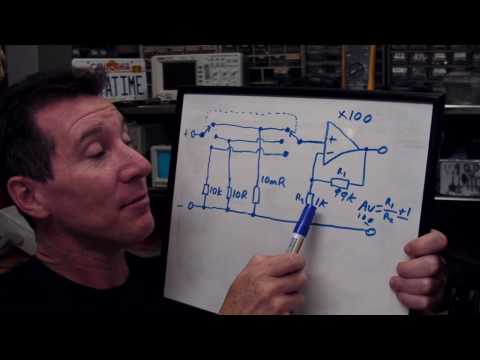

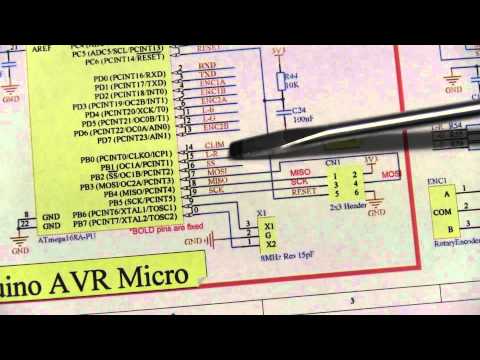

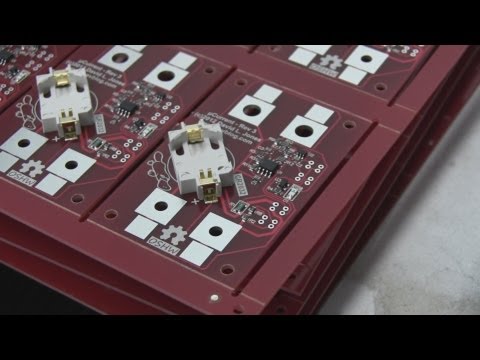

This time he updates his uCurrent PCB for production, including panelisation layout and component reel selection. Lots of the same ground is covered as in part 1, but with a specific real project example.

This time he updates his uCurrent PCB for production, including panelisation layout and component reel selection. Lots of the same ground is covered as in part 1, but with a specific real project example.

EEVblog #239 - PCB Design For Manufacture Part 2

EEVblog #241 - Circuit Labs PCBs from New Zealand

EEVblog #939 - How Is A PCB Manufactured?

EEVblog #72 - Let's Design a Product

EEVblog #127 - PCB Design For Manufacture Tutorial - Part 1

EEVblog #238 - Power Supply Design Part 7

EEVblog #240 - Power Supply Design Part 8

EEVblog #552 - DFM Automated PCB Panel Testing

EEVblog #990 - Getting The PCB Manufactured (Nixie PART 5)

EEVblog #1365 - Viewer PCB & Circuit Design Review

EEVblog #254 - KiCAD PCB First Impressions

EEVblog #264 - SMD PCB Pick & Place Machine Assembly

EEVblog #215 - Gaussian Resistors

EEVblog #974 - PCB Layout Walkthrough - PART 4

EEVblog #130 - The µCalc Credit Card Scientific Calculator / Computer

121GW Autoranging Speed

One of the fattest Ls #JLCPCB

EEVblog #253 - KiCAD Install & Schematic - First Impressions

EEVblog #169 - Samson StudioDock 4i USB Monitor Speaker Review

EEVblog #237 - Makerbot Thing-O-Matic Unboxing

EEVblog 1449 - What Causes Excess Battery Drain? (BM235)

EEVblog #588 - How To Do PCB Production Testing

Supernoob Dual Cap Filter PCB (Onkyo TX-8500)

#239 LM399 Voltage Reference - Quick Test

Комментарии

0:56:54

0:56:54

0:16:39

0:16:39

0:27:00

0:27:00

0:51:03

0:51:03

0:50:46

0:50:46

0:27:00

0:27:00

0:34:01

0:34:01

0:30:01

0:30:01

0:42:31

0:42:31

0:45:10

0:45:10

1:03:04

1:03:04

0:30:05

0:30:05

0:32:49

0:32:49

1:13:59

1:13:59

0:20:51

0:20:51

0:03:31

0:03:31

0:01:01

0:01:01

0:45:01

0:45:01

0:16:39

0:16:39

0:33:27

0:33:27

0:19:54

0:19:54

0:14:35

0:14:35

0:00:38

0:00:38

0:13:48

0:13:48