filmov

tv

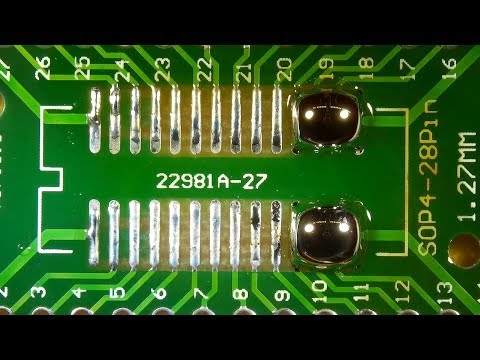

EEVblog #437 - Removing SMD Parts with ChipQuik

Показать описание

How to remove surface mount SMD QFP packages from a PCB using ChipQuik low melting point alloy solder.

EEVblog Main Web Site:

EEVblog Amazon Store:

Donations:

Projects:

Electronics Info Wiki:

EEVblog Main Web Site:

EEVblog Amazon Store:

Donations:

Projects:

Electronics Info Wiki:

EEVblog #437 - Removing SMD Parts with ChipQuik

Desoldering cpu #JLCPCB #cpu #desoldering #electronic #processor #shorts

Desoldering IC without hot air station #electronic #how #howto #smd #process #desoldering #hotair

EEVblog #434 - SMD Thermal Pad & Drag Soldering Tutorial

SMD Desoldering | How to solder smd components 🔥🔥#shorts #youtubeshorts

Is it possible to unsolder a smd chip using thermal paste? #smd #chip #soldering

#ic chip Grinding scratching#viral #shot

I Never Expected That! EPIC ENDING! #shorts #repair #xboxrepair #xboxseriesx #microsoldering

Remember To Use Hot Air And Suction Pen When Removing Large IC!

How to remove smd chip without hot air

How to Replace a 304 pin IC #how #to #solder #arcade #repair

Crazy, dangerous, and messy desoldering method

Dead Micro Chip SMD swap | Resolder #shorts #microsoldering #smdsoldering #fpvrepair #bandifpv #asmr

SMD soldering newbie tries to replace a MPU6000

How to Remove SMD Components Without Hot Air Gun Tips and Tricks

How to desolder USB flash TSOP-48 chip with hot air

How to Remove and Solder a SOIC 14 SMD Chip

Wiha Precision Chip Lifter #electronics #tools #review

Desoldering without hot air

How to Remove SMD Components Without Hot Air Gun [How To Remove SMD Components With Soldering Iron]

EEVblog #435 - 3D Rocker Teardown

Chip desoldering (HDD controller)

Ic Remove Without SMD 🔥 #youtubeshorts #shorts #viral @SelubhaiGsm @harkeshmobilecare

EEVBlog #438 - Amiga 500 Retro Computer Teardown

Комментарии

0:20:47

0:20:47

0:00:29

0:00:29

0:00:58

0:00:58

0:18:12

0:18:12

0:00:15

0:00:15

0:00:12

0:00:12

0:00:16

0:00:16

0:01:00

0:01:00

0:00:12

0:00:12

0:03:57

0:03:57

0:00:48

0:00:48

0:00:16

0:00:16

0:01:00

0:01:00

0:16:57

0:16:57

0:10:03

0:10:03

0:00:16

0:00:16

0:02:33

0:02:33

0:00:59

0:00:59

0:07:32

0:07:32

0:02:08

0:02:08

0:20:50

0:20:50

0:00:15

0:00:15

0:00:16

0:00:16

0:40:58

0:40:58