filmov

tv

EEVblog #1139 - OCXO Oven Oscillator Repair

Показать описание

Well, repair-ish. Fixing the adjustment issue in the Systron Donner oven crystal oscillator. More issues found though.

Support the EEVblog through Patreon!

Buy anything through that link and Dave gets a commission at no cost to you.

Stuff I recommend:

Donate With Bitcoin & Other Crypto Currencies!

Support the EEVblog through Patreon!

Buy anything through that link and Dave gets a commission at no cost to you.

Stuff I recommend:

Donate With Bitcoin & Other Crypto Currencies!

EEVblog #1139 - OCXO Oven Oscillator Repair

#93 10MHz OCXO Ovenized Crystal Oscillator Test

EEVblog #1138 - Systron Donner Counter Teardown

EEVblog #1140 - 3 CENT Micro LED Blinky with ICE!

EEVblog #1141 - Padauk 3 CENT Micro - Programmer

EEVblog #1137 - Mailbag Monday

FranLab Evicted!

Fixing the flooded ocxo oscilator?

OCXO hermetically sealed? Is it really?

EEVblog #1151 - Dumpster Dive Yamaha Receiver

EEVblog 1407 - Right to Repair with iFixit Founder Kyle Wiens

The EEVblog Lab is moving!

EEVblog #1142 - EEVblog LAB Tour - Before

EEVblog #1136 - Banksy Artwork Shredder - Part 2 (Still Trolling!)

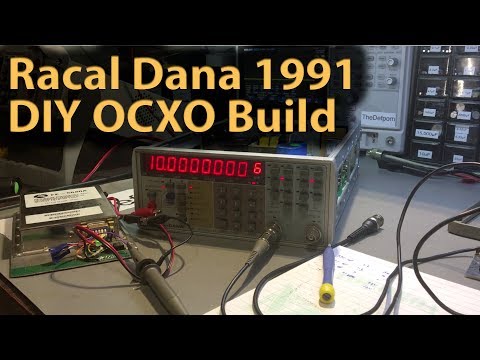

#237 Racal Dana 1991 DIY 10MHz OCXO Build

Youtube Community Strike! - w00t!

EEVblog #1134 - Dumpster Diving Teardown Tuesday

🔴 #439 Mailbag Monday 17th September 2018 - Rohde & Schwarz OCXO and more.

Homebrew OCXO temperature sweep

EEVBlog #1145 - Dumpster Diving 4K TV!

How Do Ballistic Missile Defense Systems and OCXO Work?

EEVblog #1121 - Fontus goes BANKRUPT!

EEVblog #1147 - 1 Cent Regulator! That's MAD!

Rigol MSO5000 Bug Bonanza

Комментарии

0:14:22

0:14:22

0:03:48

0:03:48

0:26:19

0:26:19

0:27:25

0:27:25

0:19:42

0:19:42

0:25:16

0:25:16

0:05:33

0:05:33

0:02:39

0:02:39

0:02:58

0:02:58

0:13:54

0:13:54

0:27:06

0:27:06

0:06:54

0:06:54

0:17:07

0:17:07

0:21:22

0:21:22

0:54:29

0:54:29

0:10:21

0:10:21

0:14:37

0:14:37

0:13:26

0:13:26

0:04:07

0:04:07

0:18:57

0:18:57

0:05:26

0:05:26

0:19:58

0:19:58

0:29:50

0:29:50

0:39:39

0:39:39