filmov

tv

JB Weld, Does it Work?

Показать описание

This video is about JB Weld, Does it Work? Does J-B Weld work? I have to affiliation with this company and this review is 100% unbiased.

No nonsense, honest review on a popular product.

No nonsense, honest review on a popular product.

JB Weld Metal Repair Paste Reviews - Does it Really Work?

How to use JB Weld | JB Weld Original Cold Steel | JB Weld Step-by-Step Instructions

JB Weld, Does it Work?

How to use JB Weld Original Cold Weld Steel Reinforced Epoxy, plus Review

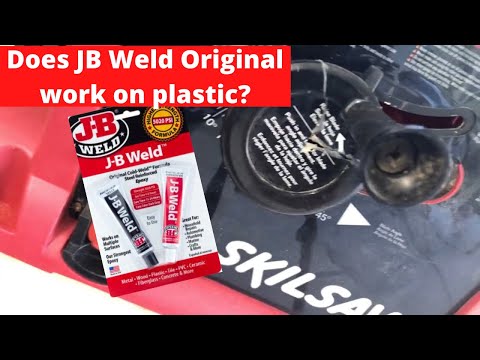

Does JB Weld work on plastic?

JB weld good for metal | Does it Work #shorts

How to Use JB Weld SteelStik | Step-by-Step Instructions

JB Weld Original Cold Weld Epoxy to fix leak on Pool Filter at Pressure Gauge… Success

Can JB Weld Fix This Porsche Cylinder Head Bolt Hole? - I ❤️ My 944

How strong is JB weld structural epoxy adhesive anyways ? Destructive test, simulation and review

JB Weld Original Cold Steel VS JB Weld Kwikweld Head to Head Comparison

Is JB Weld Strong Enough to Repair a Broken Connecting Rod? Let's Find Out!

JB WELD for Rust Holes?

how good is jb weld? actually waterproof /gas resistant?

How to Use JB Weld Clearweld Step-by-step Instructions

How To Use J-B Weld Epoxy Putty Sticks

HOW TO USE J-B WELD SYRINGE EPOXIES AND ADHESIVES

Does Regular JB Weld Work on Wood?

The Ultimate JB Weld Strength Test (Lifting a Car)

J-B Weld FiberWeld Repair Cast

automotive fix all jb weld 👨 car 🚗

How to Use JB Weld

How to use JB Weld | JB Weld Original Cold Steel | JB Weld Step-by-Step Instructions

Using JB Weld to Fix Rust Holes?

Комментарии

0:00:24

0:00:24

0:03:46

0:03:46

0:06:41

0:06:41

0:01:53

0:01:53

0:02:32

0:02:32

0:00:12

0:00:12

0:03:49

0:03:49

0:01:01

0:01:01

0:27:56

0:27:56

0:09:19

0:09:19

0:02:14

0:02:14

0:05:31

0:05:31

0:00:53

0:00:53

0:00:49

0:00:49

0:01:38

0:01:38

0:00:49

0:00:49

0:00:53

0:00:53

0:02:46

0:02:46

0:12:40

0:12:40

0:01:03

0:01:03

0:00:16

0:00:16

0:01:54

0:01:54

0:02:11

0:02:11

0:05:46

0:05:46