filmov

tv

Is JB Weld Strong Enough to Repair a Broken Connecting Rod? Let's Find Out!

Показать описание

JB Weld Original is a terrific epoxy. However, every product has its limits. So, is JB Weld strong enough to repair a connecting rod that broke into 5 pieces? Let's find out!

Products Tested In This Video (in no particular order):

Videography Equipment:

➡ As an Amazon Associate I earn from qualifying purchases.

This video is only for entertainment purposes. If you rely on the information portrayed in this video, you assume the responsibility for the results. Project Farm LLC

Products Tested In This Video (in no particular order):

Videography Equipment:

➡ As an Amazon Associate I earn from qualifying purchases.

This video is only for entertainment purposes. If you rely on the information portrayed in this video, you assume the responsibility for the results. Project Farm LLC

Is JB Weld Strong Enough to Repair a Broken Connecting Rod? Let's Find Out!

How strong is JB weld structural epoxy adhesive anyways ? Destructive test, simulation and review

JB Weld Strength Test

The Ultimate JB Weld Strength Test (Lifting a Car)

How to use JB Weld | JB Weld Original Cold Steel | JB Weld Step-by-Step Instructions

JB Weld, Does it Work?

The Ultimate Epoxy Competition--Which Epoxy is the Best?

JB Weld! They still sell this stuff? Does it work?

Bass Boat Build Pt.2 (Sanding & Sealing)

Is Flex Glue better than JB Weld, Gorilla & Loctite? Let's find out!

Does Regular JB Weld Work on Wood?

Which Epoxy Putty Brand is Best? JB Weld, Gorilla, Oatey, POR 15, QuickSteel, PC-7

Top 5 Best Glue for Metals Review [2022] | See This Before You Buy

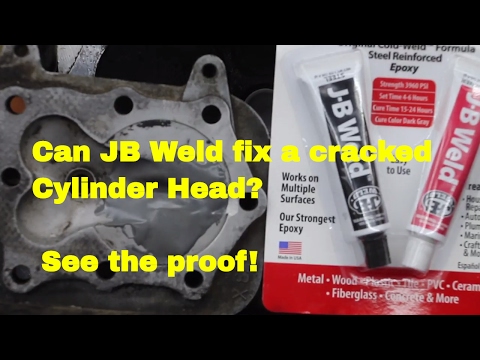

Can JB Weld fix a cracked cylinder head? See the proof!!

What is J-B Weld for? How To Repair With J-B Weld

How to use JB Weld Original Cold Weld Steel Reinforced Epoxy, plus Review

JB Kwik JB Quick Cold Weld Fixes The Unfixable Quickly Strong 2 Part Steel Reinforced Epoxy Glue

The Best Way To Use JB Weld

How to Use JB Weld

How To Use J-B Weld Epoxy Putty Sticks

Fix An Exhaust Leak with JB WELD (Easy)

JB weld good for metal | Does it Work #shorts

Jb Weld Can Repair Steel - Aluminum - Anything

JB Weld SteelStik Review-Real Life Use

Комментарии

0:05:31

0:05:31

0:09:19

0:09:19

0:04:05

0:04:05

0:12:40

0:12:40

0:03:46

0:03:46

0:06:41

0:06:41

0:13:08

0:13:08

0:00:13

0:00:13

0:20:35

0:20:35

0:16:10

0:16:10

0:02:46

0:02:46

0:17:46

0:17:46

0:04:18

0:04:18

0:12:05

0:12:05

0:05:39

0:05:39

0:01:53

0:01:53

0:35:53

0:35:53

0:06:14

0:06:14

0:01:54

0:01:54

0:00:49

0:00:49

0:03:02

0:03:02

0:00:12

0:00:12

0:17:34

0:17:34

0:06:15

0:06:15