filmov

tv

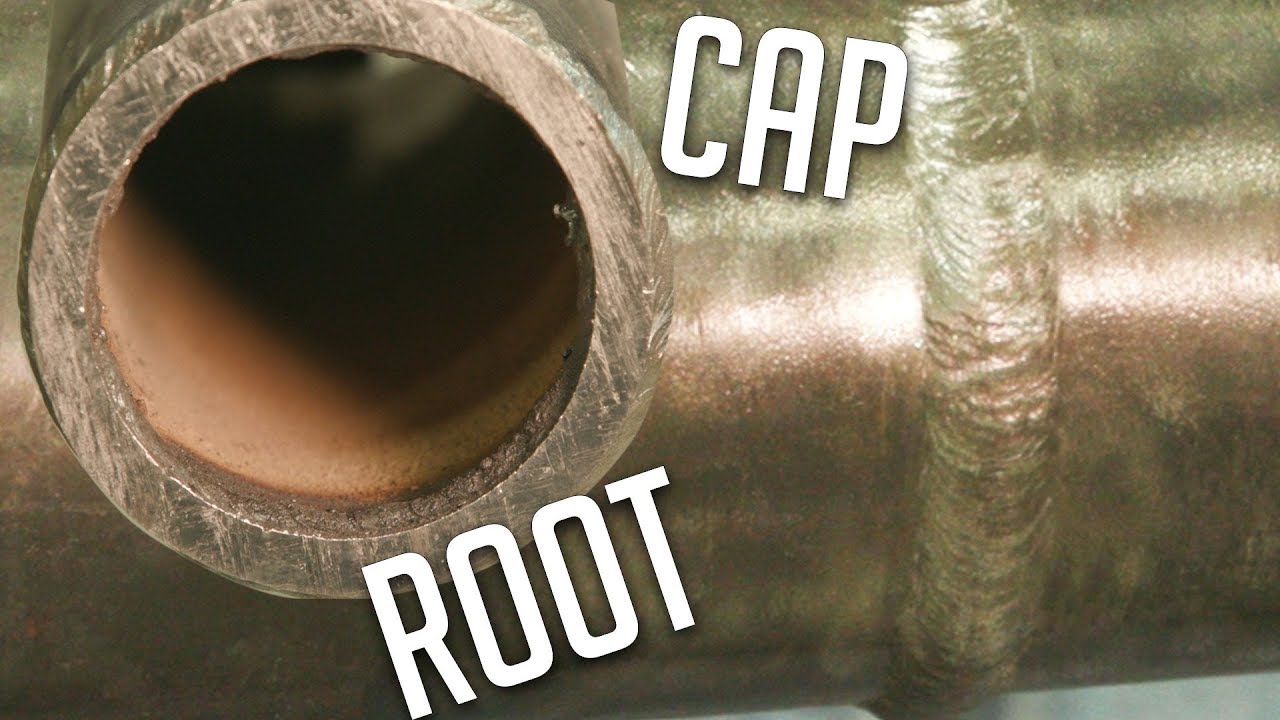

6010 Open Root Pipe Welding

Показать описание

Today is 6010 open root pipe welding! We're going to show you the welding technique to put in that 6010 open root, followed by some handy tips and tricks for burning in the hot pass and getting a nice even cap without undercut and keeping your cap between flush and 1/8".

Talk with Bob, Jason and Mancub!

------------------------------------------------

EQUIPMENT WE LIKE AND USE IN THE SHOP:

VIDEO SCHEDULE:

MONDAY @ 5:30 PM ET

WEDNESDAY @ 5:30 PM ET

FRIDAY @ 5:30 PM ET

#welddotcom

Talk with Bob, Jason and Mancub!

------------------------------------------------

EQUIPMENT WE LIKE AND USE IN THE SHOP:

VIDEO SCHEDULE:

MONDAY @ 5:30 PM ET

WEDNESDAY @ 5:30 PM ET

FRIDAY @ 5:30 PM ET

#welddotcom

Pipe Welding for Iron Workers | 6010 Open Root

6010 Open Root Pipe Welding

Stick Welding 3G Uphill 6010 Open-Root #shorts

Stick Welding Techniques 6010 Downhill

Stick Welding Tips for 6010 Open Root &7018 fill cap

6010 ROOT TIPS & TRICKS | VERY DETAILED, HIGHLY REQUESTED PIPE WELDING

6g Weld Test 6010 Root

6010 Root Pass - Whip and Pause Technique - Plate/Pipe

5G Pipe Welding Lesson 6010

6010 Open Root Welding | Quit Blowing Holes In Your Plate

6010 5/32' Open Root Practice

🔥 6G Pipe Weld - SMAW (e6010 Root/Fill 7018 Cap)

🔥 6G 6010 Roots: Old Timer vs Young Gun

🔥 6g Pipe Welding: 6010 Root 7018 Fill and Cap

6010 Downhill Root, Fill, & Cap Tips

The 6010 Blowout Repair: How to Fix the Most Common Problem in Pipe Welding

6010 Open-Root Pass with a Tight Gap #shorts

6010 METHOD OF WELDING TO THE MADNESS

5G Pipe Welding On 8' - 6010 & 7018 Weld

5G Pipe Welding 6010 Root 7018 Fill And Cap | Stick

🔥 6010 Roots and Bad Fit-up

6010 Root Pass | 3g Plate | SMAW

6010 Root Uphill with Magnetism in Pipe

🔥 Downhill Open Root 6010 with UNEVEN FITUP

Комментарии

0:13:31

0:13:31

0:08:03

0:08:03

0:00:52

0:00:52

0:10:39

0:10:39

0:08:26

0:08:26

0:06:57

0:06:57

0:10:30

0:10:30

0:11:43

0:11:43

0:04:24

0:04:24

0:11:37

0:11:37

0:06:28

0:06:28

0:13:37

0:13:37

0:17:46

0:17:46

0:19:54

0:19:54

0:10:27

0:10:27

0:11:31

0:11:31

0:00:15

0:00:15

0:11:05

0:11:05

0:33:10

0:33:10

0:09:06

0:09:06

0:14:27

0:14:27

0:04:58

0:04:58

0:08:21

0:08:21

0:07:33

0:07:33