filmov

tv

SUPER Fast Arduino Servo! ClearPath! WW120

Показать описание

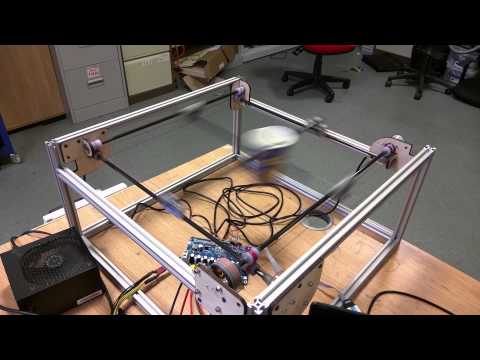

ClearPath Servos are AMAZING! Using them with an Arduino UNO to get over 1,100 IPM rapids on a linear stage!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Reach us / CNC Info:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Reach us / CNC Info:

SUPER Fast Arduino Servo! ClearPath! WW120

Arduino & ClearPath Servo: Moving 34 lbs FAST! WW131

High speed servo motor demo.

What The Differences Between Stepper Motors And Servo Motors

Motion Control with BeagleBone Black or Raspberry Pi and ClearPath-SC Servos

Arduino / ClearPath Servo Controlled Chop Saw Stop - Part 5 Final - Neo7CNC.com

[Part 1] DIY Magnetic Deburrer with Teknic Clearpath Servos and Arduino!

Difference between servo and stepper motors in CNC router

Stepper Motors vs. Servo Motors - A ClearPath Demonstration

CNC router X axis test run with Clearpath servo

Clearpath servos on the mini mill

Robotic Bartender Powered by ClearCore - Teknic's Industrial I/O & Motion Controller

Drahtschneider Arduino, Servo, Stepper

Arduino / ClearPath Servo Controlled Chop Saw Stop - Part 2 - Neo7CNC.com

Clearpath SDSK 3421S servo - testing adaptive toolpath

3D PotterBot V 3.5 with clearpath-brushless-dc-servo-motors

Slow speed FlyPT loop test - Teknic Clearpath servos

Is This $100 Motor a Clearpath-Killer? | Lathe Electronic Leadscrew - Part 26

Arduino Servo CNC Parts Loader! Part 4 WW132

6dof motion platform test sequence - AMC1280USB & Teknic Clearpath servos

ClearPath Servo Regen

Homemade DIY CNC - (AUDIO Corrected) ClearPath Servo Motors used on KR33 CNC - Neo7CNC.com

Watch ClearPath Motion Control Series Integrated Servos

ClearPath: Teknic's Integrated Digital Brushless Servo Motor and Drive

Комментарии

0:11:20

0:11:20

0:16:56

0:16:56

0:00:20

0:00:20

0:00:38

0:00:38

0:09:06

0:09:06

0:16:18

0:16:18

![[Part 1] DIY](https://i.ytimg.com/vi/Md-L-630sRI/hqdefault.jpg) 0:24:48

0:24:48

0:02:19

0:02:19

0:08:07

0:08:07

0:00:16

0:00:16

0:00:39

0:00:39

0:07:37

0:07:37

0:00:57

0:00:57

0:14:05

0:14:05

0:00:35

0:00:35

0:07:15

0:07:15

0:00:38

0:00:38

0:35:14

0:35:14

0:11:56

0:11:56

0:00:11

0:00:11

0:00:11

0:00:11

0:25:36

0:25:36

0:03:52

0:03:52

0:10:26

0:10:26