filmov

tv

Difference between servo and stepper motors in CNC router

Показать описание

Stepper motors have high torque to hold position but AC servo motors have much faster travel speed as well as high torque. Also with feedback loop servo motors keep accurate position within 5thou. In this example, both machines are running at full speed. Servo CNC on the right travels 2500 inches per minute with 50 in/sec2 acceleration while stepper runs at 900 inches per minute max speed without stalling at 20 in/sec2 acceleration

Stepper Motors vs Servo Motors: A Quick Comparison

Servo vs Stepper Motors

What The Differences Between Stepper Motors And Servo Motors

What's the difference between servo and stepper motors? | What The Tech?!

Difference between servo and stepper motors in CNC router

How to Understand the Difference Between Servo & Stepper Systems

Servo vs Stepper Motors - A Galco TV Tech Tip | Galco

difference between servo system and stepper system

Introducing Bholanath's Battery Operated Brush Cutter | Electric Brush Cutter | Bholanath

Stepper Motors vs. Servo Motors - A ClearPath Demonstration

Choosing between Servo and Stepper Motors

Servo Motor vs Stepper Motor | What is best for your project │Motion Control Training

Motion in a Minute: Servo vs Stepper motors #servomotors #steppermotor #servo #steppers

Introduction to motors. DC, Servo & Stepper.

38s Video Tell You The Differences Between Stepper Motors And Servo Motors

Webinar: Stepper vs Servo - Understanding the Differences

What's the best NEMA23 Stepper/Servo? | Electronic Leadscrew Part 24

Difference Between Stepper Motor Vs Servo Motor & Selection

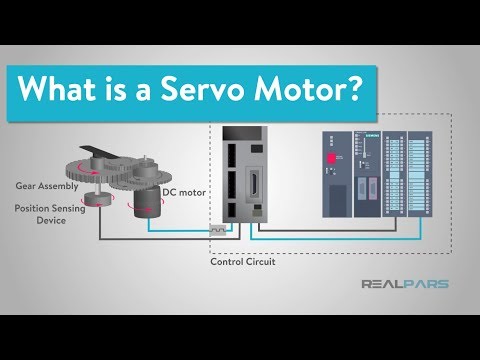

What is a Servo Motor and How it Works?

Servo Motor vs Stepper Motor ¦ Difference between Stepper Motor and Servo Motor¦

How does a Stepper Motor work?

Servo Motor vs Stepper Motor 2018

How To Select a Precision Gearbox from Sure, Servo, and Stepper at AutomationDirect

Servo Motors, how do they work?

Комментарии

0:02:17

0:02:17

0:02:32

0:02:32

0:00:38

0:00:38

0:03:16

0:03:16

0:02:19

0:02:19

0:03:57

0:03:57

0:03:08

0:03:08

0:01:15

0:01:15

0:02:34

0:02:34

0:08:07

0:08:07

0:10:05

0:10:05

0:04:01

0:04:01

0:02:15

0:02:15

0:12:33

0:12:33

0:00:38

0:00:38

0:23:14

0:23:14

0:39:25

0:39:25

0:19:11

0:19:11

0:15:45

0:15:45

0:03:08

0:03:08

0:05:53

0:05:53

0:04:26

0:04:26

0:05:14

0:05:14

0:15:12

0:15:12