filmov

tv

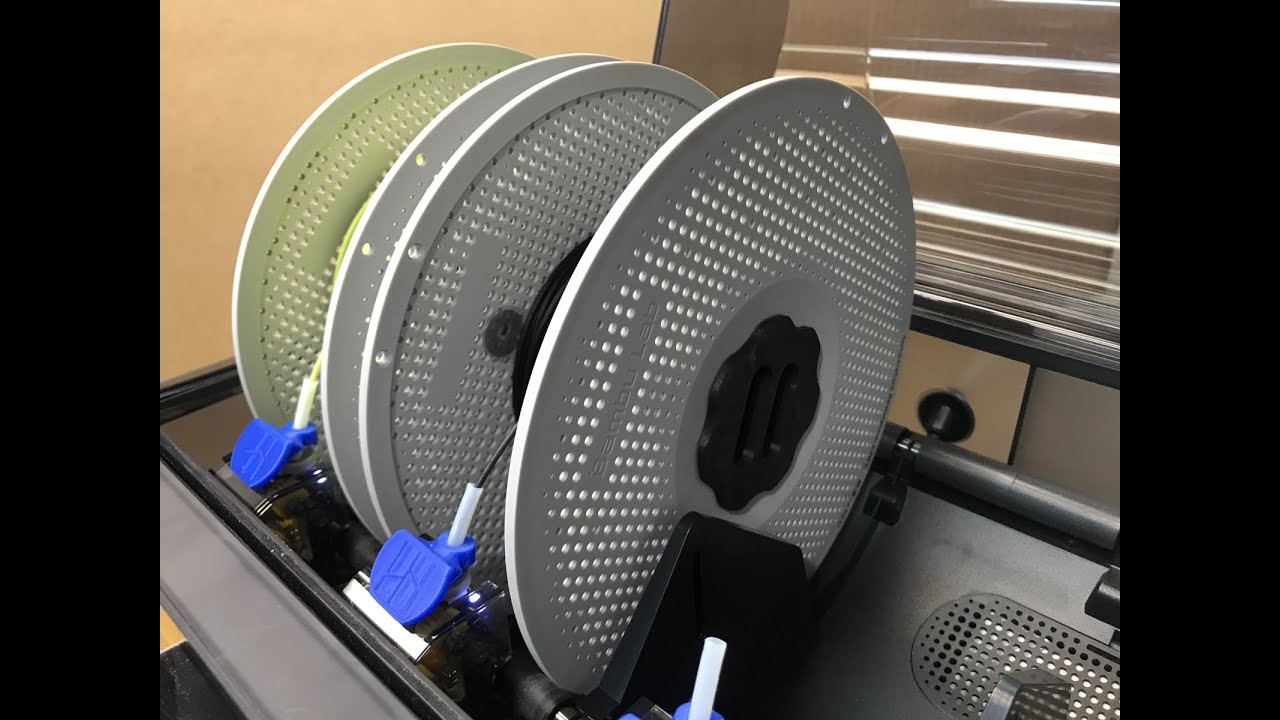

Fix for Bambulab AMS stuck spool

Показать описание

Adding weight to the filament spool is a way to fix the jamming problem while loading or unloading the filament in the Bambulab's AMS.

Fix for Bambulab AMS stuck spool

Fix for Bambulab AMS stuck spool, short video

How to Clear Broken Filament from the Bambu Lab AMS

How To Clear Broken Filament Jam From A Bambu Lab AMS (It's Easy!)

Bambu lab error stuck filament and how to fix

Solving Common AMS Problems on Your Bambu Lab 3D Printer: Tips and Tricks

How to Fix Bambu AMS Filament Stuck in Path! | Easy DIY Fix

Bambu AMS funnel loading problem

Bambu lab AMS clog fix tutorial, failed to pull out the filament from the extruder issue

How to unjam filament in AMS unit of Bambu Lab X1 Carbon

Filamentstau, Filament gebrochen, im AMS des Bambu Lab beheben! So einfach geht es!

Unclog your Bambu Lab AMS! Filament stuck in your AMS, lets fix it!

Bambu Lab's X1 and X1C Failed to pull out filament - Quick and simple fix

Bambulab AMS failing to load

Simple Button Improvement for the BambuLab AMS!

fix for bambu ams pull back error.

Red LED in the Bambulab AMS? How to fix the stuck filament! filament!

defective AMS first-stage feeder

quick fix for stuck filament in extruder of my bambu 3d printer #3dprinting

Bambu Labs X1 Carbon, P1P, P1S filament stuck in extruder issue fixed!

Fixing the BambuLab AMS first stage feeder!

▼ Removing STUCK FILAMENT from the Bambu Labs AMS ▼

A simple fix for the Bambu Labs AMS filament roller!

Fixing my AMS #3dprinting

Комментарии

0:02:15

0:02:15

0:00:15

0:00:15

0:08:25

0:08:25

0:06:04

0:06:04

0:00:56

0:00:56

0:04:09

0:04:09

0:06:08

0:06:08

0:00:47

0:00:47

0:07:24

0:07:24

0:01:24

0:01:24

0:06:18

0:06:18

0:03:02

0:03:02

0:04:41

0:04:41

0:00:10

0:00:10

0:01:04

0:01:04

0:02:01

0:02:01

0:00:31

0:00:31

0:00:30

0:00:30

0:01:01

0:01:01

0:01:59

0:01:59

0:04:45

0:04:45

0:04:46

0:04:46

0:00:58

0:00:58

0:00:49

0:00:49