filmov

tv

Print FASTER: Tuned Profiles or Drilled Nozzles?

Показать описание

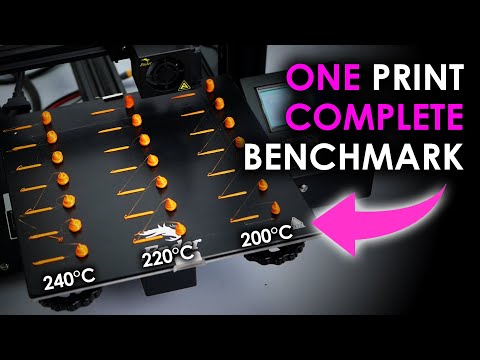

Drilling out nozzles seems to be all the rage today - but does that actually get your prints done faster or are you better off cranking up speeds and accelerations in the slicer?

Product links are affiliate links - I may earn a commission on qualifying purchases (at no extra cost to you)

Product links are affiliate links - I may earn a commission on qualifying purchases (at no extra cost to you)

Print FASTER: Tuned Profiles or Drilled Nozzles?

Print Faster with Custom Cura Profiles for Ender 3 and Ender 3 Clones

5 things to check & tune to 3D print faster

Easy Hotend Benchmark for FAST PRINTING Profiles

5 Slicer defaults I ALWAYS change #3DP101

Print Faster on Your Ender 3 Style Printer Using Tricks in Cura

The Hidden Cost of 0.4mm Nozzles!

How to 3D Print faster using a .6mm nozzle! My updated Cura settings for speed & quality!!

The Ultimate Guide to Perfect 3D Prints

TOP 5 TIPS for Tuning your 3D Printer Faster with Klipper

Tuning LW-PLA Profiles for Speed in Prusaslicer 2.5.2

Teachable Moments: How I Tuned My Voron V2 Printer for Faster Print Speeds

Let's tune a 0.8mm Nozzle on my Anycubic Mega X: Part 3

Tuning PrusaSlicer for speed, and quality

How I tune in new filaments!

0.4mm nozzles just became obsolete

Creality Ender 3 V2 - Simple Tips for Super Clean 3D Prints

Remove ringing by tuning acceleration and junction deviation - step by step guide

Fast prusa 3D print 350% print speed

How to tune your slicer settings featuring Ender 3 - UPDATE IN DESCRIPTION

3D printer calibration site V2 - Still free and better than ever!

Creality Ender 3 V2 - My Cleanest Print Ever and You Can Too!

3-D print going 999 speed

Creality Ender 3 V2 - Speed up prints without sacrificing quality by turning on this setting

Комментарии

0:16:29

0:16:29

0:07:33

0:07:33

0:13:18

0:13:18

0:15:54

0:15:54

0:15:27

0:15:27

0:06:54

0:06:54

0:00:21

0:00:21

0:11:16

0:11:16

0:17:27

0:17:27

0:11:02

0:11:02

0:07:50

0:07:50

0:51:10

0:51:10

0:01:01

0:01:01

0:41:17

0:41:17

0:11:25

0:11:25

0:15:32

0:15:32

0:08:26

0:08:26

0:17:19

0:17:19

0:00:41

0:00:41

0:11:12

0:11:12

0:10:40

0:10:40

0:03:57

0:03:57

0:00:07

0:00:07

0:07:02

0:07:02