filmov

tv

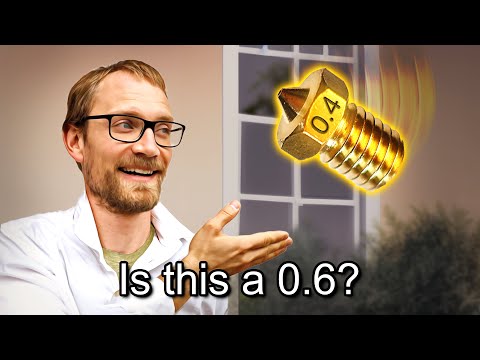

0.4mm nozzles just became obsolete

Показать описание

Are you still using a 0.4mm nozzle? You probably shouldn’t be!

Models shown

Relevant products

Product links are affiliate links - I may earn a commission on qualifying purchases (at no extra cost to you)

Models shown

Relevant products

Product links are affiliate links - I may earn a commission on qualifying purchases (at no extra cost to you)

0.4mm nozzles just became obsolete

The Hidden Cost of 0.4mm Nozzles!

Dump your 0.4mm nozzle! #shorts

Are 0.4 Nozzles Really Obsolete in Cura V5.1?

0.2mm vs 0.4mm nozzles

When To Switch your .4 nozzle for a .6 nozzle?

Get the benefits of a 0.6mm nozzle with a 0.4?

Clay Printing the first layer, 0.8mm diameter nozzle

3D Print Fine Details by using smaller nozzles

3D Printing Nozzle Size Comparison (0.2 vs 0.4 vs 0.6 vs 0.8mm Nozzle)

An Impossible 3D Printer Nozzle 😱

Tiniest nozzle makes tiniest 3D print

1mm nozzle test

3D PRINT HORROR! 4MM Nozzle??? #SHORTS

Choosing the BEST Nozzle Size For Your 3D Printer!

3D Printing Micro 0.2mm Nozzle Clear Filament 🤔

Tiny vs Giant 3D Printer Nozzles 🔎

0.4mm Nozzle - Extra Wide Extrusions, Not So Easy

Volcano is Obsolete: Just use Nuts!

0.4mm vs. 0.8mm 3D Printer Nozzle Test

5 Easy Tips for Micro 3D print with 0.4 mm nozzle

Max line width ? / 0,8 mm nozzle vs. 0,4 mm

Getting QUALITY 3D Prints using a Larger Nozzle! | Step by Step Cura 0.8mm Profile Setup

Creality3D 0.4mm Nozzle for 3D Printer - Gearbest.com

Комментарии

0:15:32

0:15:32

0:00:21

0:00:21

0:00:58

0:00:58

0:05:14

0:05:14

0:00:54

0:00:54

0:09:50

0:09:50

0:11:28

0:11:28

0:00:25

0:00:25

0:01:00

0:01:00

0:05:21

0:05:21

0:00:48

0:00:48

0:00:58

0:00:58

0:00:21

0:00:21

0:00:34

0:00:34

0:18:08

0:18:08

0:00:52

0:00:52

0:00:21

0:00:21

0:03:27

0:03:27

0:13:30

0:13:30

0:06:59

0:06:59

0:03:14

0:03:14

0:06:44

0:06:44

0:13:17

0:13:17

0:00:11

0:00:11