filmov

tv

Easy Hotend Benchmark for FAST PRINTING Profiles

Показать описание

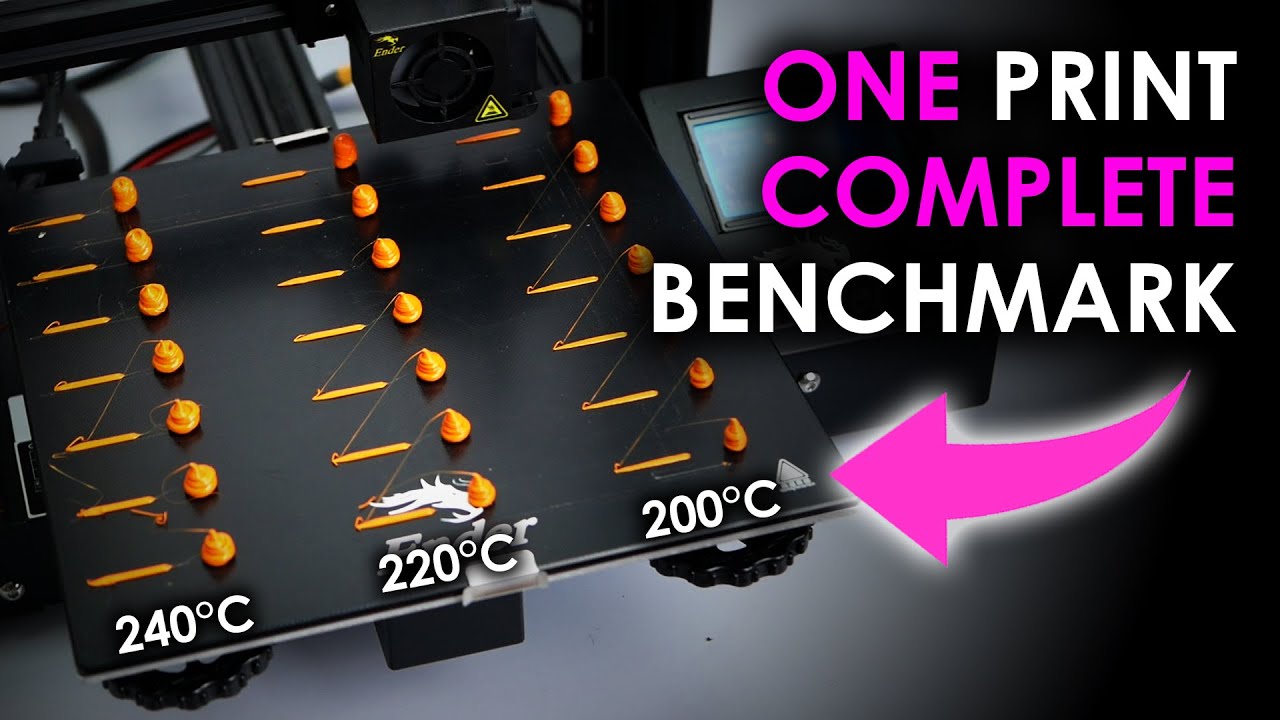

If you want to print fast, you need to benchmark your hotend! I made this super simple by creating a simple tool that you can use to create a test G-Code that will help you to find out what the performance of your hotend really is! Using this knowledge, we’ll go over how you can create a fast draft printing profile in PrusaSlicer and basically any other slicer to print for example this part right here 160% faster on a cheap Ender-3!

💚 Support me 💚

Join as a YouTube member!

🛒 Equipment used in this video (affiliate):

🖨 Printed models:

🎥 Related videos:

⚙ My gear (Affiliate Links):

🎥 CAMERAS & LENSES

🎙AUDIO

🔴 LIVE STREAMING

Chapters

00:00 Introduction

01:12 What is FAST printing?

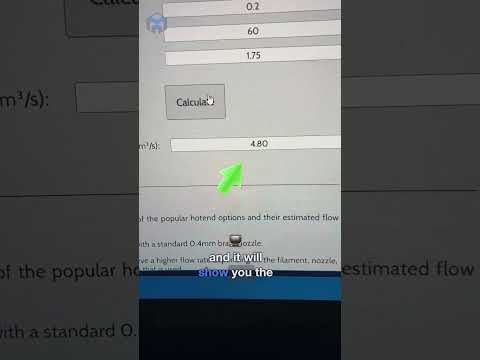

02:31 Extrusion System Flow Capability

03:55 Benchmarking Tool

05:45 Temperature Dependence

08:14 Creating a SPEED PROFILE in PrusaSlicer

13:53 Sponsored Segment

#3dprinting #benchmark

DISCLAIMER: This video was sponsored by NordPass.

Easy Hotend Benchmark for FAST PRINTING Profiles

How fast can your hotend print?

Find Your 3d Printers MAX Output

High Speed Printing: Hot End, Temperatures, Silicone Sock and Materials

How to find the best HotEnd? - Ultimate HotEnd Testing - Episode #1

The ONE GAME-CHANGING Slicer SETTING... (Huge 3D Print Quality BOOST)

Speed Boost for Your 3D Printer!

5 things to check & tune to 3D print faster

smoother prints with high flow hotend. #3dprinting #3d #prototype

3D Printing Volumetric Flow Rate Calculator

Benchmark test High Flow Rapido Hotend mit bis zu 55mm³/s - so geht's!

200mm/s Printing Speed: The Ender 3 V2 Stock 3D Printer in Action

Volcano is Obsolete: Just use Nuts!

Stop 3d printing so slow!!! 🤯 (how to print faster)

Fast 3D printing is bad for Strength! (and how to fix it!)

Rapido Hotend Replacement Parts on EVA3 Toolhead

printed WITHOUT support #shorts

#3dprinting tuning. Coarse Flow Rate test and decision time.

Rapido hotend Maximum Practical Flow Rate Test

10 Tips 10 Days - Day 1 - Print Speed vs Hotend Temperature, or how to print a lot faster.

Fast TPU - 200mm/sec - 10mm3 flow - Rapido

Easiest upgrade for a 3D printer CHT nozzles by Bondtech #shorts

Will These 3D Printer Upgrades Increase Printing Speed And Quality?

Bi-Metallic Heat Breaks - A (R)Evolution?!

Комментарии

0:15:54

0:15:54

0:10:04

0:10:04

0:07:18

0:07:18

0:15:01

0:15:01

0:21:25

0:21:25

0:07:34

0:07:34

0:00:15

0:00:15

0:13:18

0:13:18

0:00:16

0:00:16

0:00:38

0:00:38

0:03:34

0:03:34

0:00:16

0:00:16

0:13:30

0:13:30

0:04:14

0:04:14

0:15:11

0:15:11

0:00:26

0:00:26

0:01:00

0:01:00

0:00:15

0:00:15

0:00:27

0:00:27

0:03:00

0:03:00

0:00:18

0:00:18

0:00:12

0:00:12

0:09:01

0:09:01

0:15:26

0:15:26