filmov

tv

The Hidden Cost of 0.4mm Nozzles!

Показать описание

#shorts #3dprintfarm #3dprintingservice #3dprinting #3dprinterfarm #3dprintingbusiness

Keep up with us on social media!

3DQue Systems is a technology startup that is focused on automating 3D printers to make high-volume production and innovation available to engineers, entrepreneurs, and makers around the world. With our YouTube channel we hope to be a resource for people interested in high-volume production using 3D printers.

Keep up with us on social media!

3DQue Systems is a technology startup that is focused on automating 3D printers to make high-volume production and innovation available to engineers, entrepreneurs, and makers around the world. With our YouTube channel we hope to be a resource for people interested in high-volume production using 3D printers.

The Hidden Cost of 0.4mm Nozzles!

0.2mm vs 0.4mm nozzles

0.4mm nozzles just became obsolete

3D Printed Pin Support Challenge 😱

Finding Out How Much This Diamond is Worth

How should your ring fit? 💍

TURN YOUR GOLD INTO CASH!!!! #shorts

Never do these three things to your Posca Marker!

What Could Cause Kidney Stones (Animation)

Colored Diamonds Are RARE… Here’s Why!

Can I See the Flag On the Moon Through My Telescope #shorts

Do THIS to make your gloves last longer #shorts #asmr #goalkeeper

Do you know the correct method of stranded wire?

DIY Sheet Metal Bending Tools #shorts

THE BIG SECRET about trimmer line on any brand like Stihl, Echo, Husqvarna, to SAVE YOU TONS MONEY!

Drill Bits #shorts

What's the best method for piercing your ears?

MAKING BUSTA RHYMES @bustarhymes BIGGEST DIAMOND CUBAN SETUP !!! #shorts

HOW MUCH DO THESE GOLD CUBANS WEIGH!?!?! #shorts

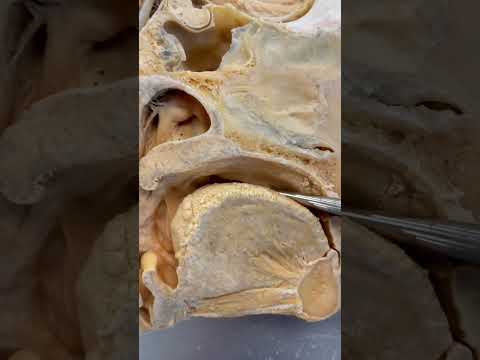

Looking at a REAL Human Tongue

0.5 vs 0.7 vs 2.0 mm Lead Size #shorts #SYShorts 190

electrician tips: how to joint electric wires

Handmade Miami Cubanlink Chain Necklace 12mm Solid 925 Sterling Silver Men size 22-30' Free Shi...

Nozzle Big Mama

Комментарии

0:00:21

0:00:21

0:00:54

0:00:54

0:15:32

0:15:32

0:00:35

0:00:35

0:00:35

0:00:35

0:00:15

0:00:15

0:01:00

0:01:00

0:00:23

0:00:23

0:00:33

0:00:33

0:00:24

0:00:24

0:00:41

0:00:41

0:00:34

0:00:34

0:00:39

0:00:39

0:00:20

0:00:20

0:08:13

0:08:13

0:00:31

0:00:31

0:00:30

0:00:30

0:01:00

0:01:00

0:00:58

0:00:58

0:00:39

0:00:39

0:00:45

0:00:45

0:00:08

0:00:08

0:00:16

0:00:16

0:00:08

0:00:08