filmov

tv

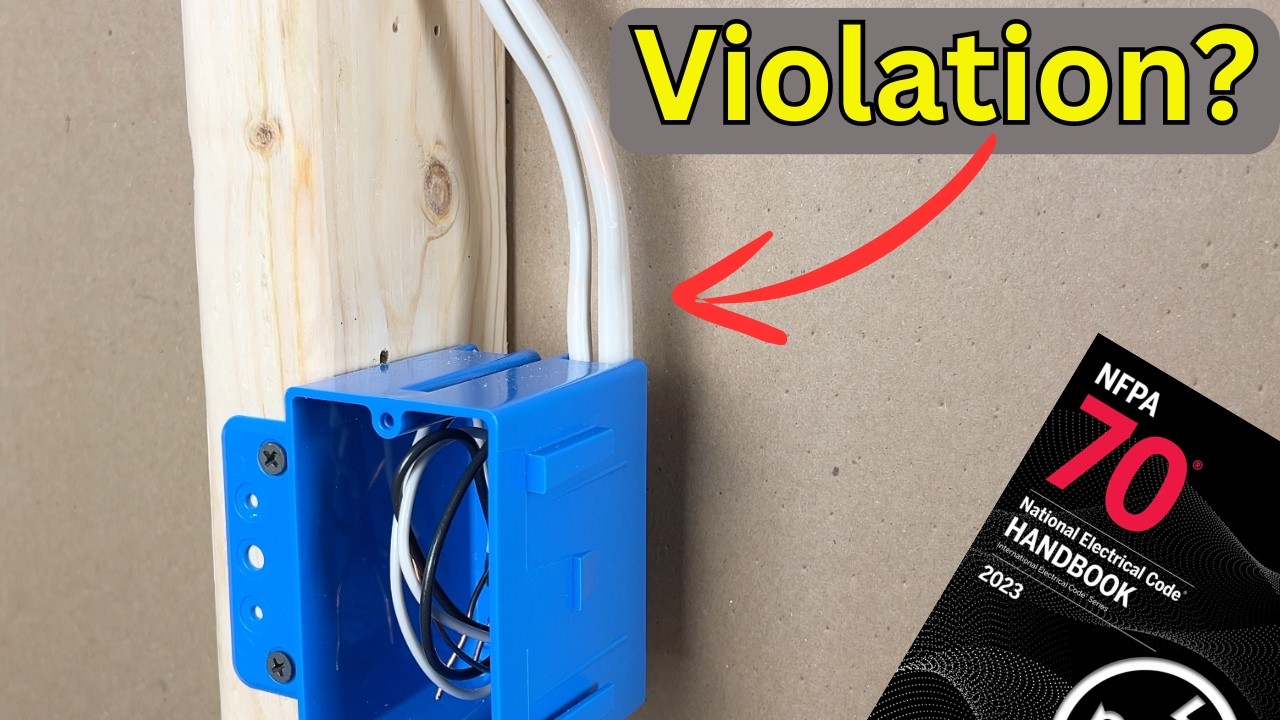

6 Electrical Code Myths people Should Stop Believing

Показать описание

In this video we will clear up 6 myths about electrical code requirements that many DIYer and even many electricians should stop believing.

FlexiSpot is having their anniversary sale now and a chance to win free orders! 🌟 Use my code ''24AUGE7PLUS” for extra $50 off on E7 PLUS! Trust me, it's a rare treat!

DESK: “4-leg”, “FlexiSpot”, “ E7 Plus Standing Desk” , “FlexiSpot E7 Plus” , “Ergonomic Desk”.

🛠️ Affiliate links: (Best Hand Tools) The ones I use daily.

🛠️Wire Connectors

🎥 Recording Gear

☑️ All links shared in video descriptions/comments are affiliate links that help support the channel with no extra cost to you.

⚡️ More Educational (Electrical Videos)

FlexiSpot is having their anniversary sale now and a chance to win free orders! 🌟 Use my code ''24AUGE7PLUS” for extra $50 off on E7 PLUS! Trust me, it's a rare treat!

DESK: “4-leg”, “FlexiSpot”, “ E7 Plus Standing Desk” , “FlexiSpot E7 Plus” , “Ergonomic Desk”.

🛠️ Affiliate links: (Best Hand Tools) The ones I use daily.

🛠️Wire Connectors

🎥 Recording Gear

☑️ All links shared in video descriptions/comments are affiliate links that help support the channel with no extra cost to you.

⚡️ More Educational (Electrical Videos)

6 Electrical Code Myths people Should Stop Believing

5 Electrical Code Lies DIYers Should Stop Believing!

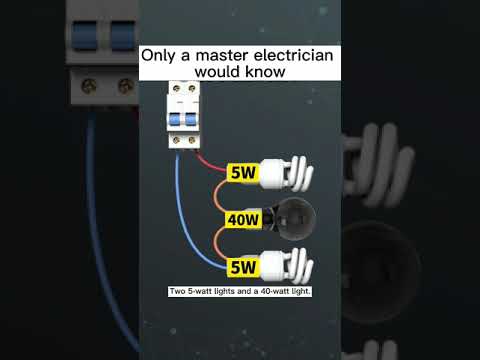

Only the master electrician would know

Ground is a Myth says the ARRL! Ground is NOT a Myth and Here's How I Grounded My Station W6LG ...

#1 DIY Electric Mistake - Can you use Romex Wire in Conduit?

The Most Common Code Violation!!!

AVOID These MISTAKES In Black Myth Wukong 🤯👀

Did you know in Black Myth Wukong?

Ground is a Myth! | 2024 ARRL National Convention

WHO ARE YOU Playing As in Black Myth: Wukong? (Is it Sun Wukong?) 🙉🐲 #blackmythwukong

There’s a lot of myths and hype around waist trainers ! Use code KAM15 for 15% off

Myth vs fact 2

Debunking myths

In Black Myth Wukong, You’re Not Playing As Sun Wukong

25 Among Us Myths Tested to See if They Work

How To Get The SECRET Gourd & Spirit In Black Myth: Wukong - Chapter 2

Get OVERPOWERED Staff EARLY In Black Myth Wukong 🤯👀

Check this CODE Before Buying New Tires! #Shorts

How To Get The Best SECRET Weapon In Black Myth: Wukong - Chapter 2

Fortnite makes no sense...

5 Myths in GTA 5 #shorts

Who will dance with the baby? 💃✨

WHEN THE LITTLE LAMBORGHINI COMES TO LIFE 😳 - #shorts

I-Team: Hidden cameras reveal dark side of solar power

Комментарии

0:10:14

0:10:14

0:05:25

0:05:25

0:00:07

0:00:07

0:12:26

0:12:26

0:03:44

0:03:44

0:04:42

0:04:42

0:01:01

0:01:01

0:00:59

0:00:59

0:46:05

0:46:05

0:00:40

0:00:40

0:00:26

0:00:26

0:00:34

0:00:34

0:00:40

0:00:40

0:01:01

0:01:01

0:11:53

0:11:53

0:00:58

0:00:58

0:01:01

0:01:01

0:00:58

0:00:58

0:01:00

0:01:00

0:00:15

0:00:15

0:00:39

0:00:39

0:00:10

0:00:10

0:00:15

0:00:15

0:06:21

0:06:21