filmov

tv

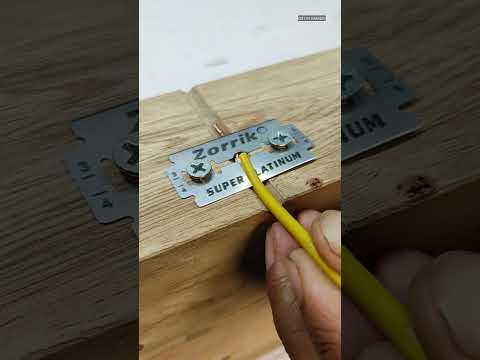

DIY Wire Stripping Jig

Показать описание

The DIY Wire Stripping Jig

•••

I needed some bare wire to make a power bus for my marble machine motors. After unsuccessfully trying to use wire strippers and a knife, I stumbled upon this method. Using a scrap 3d print, I drilled an extra hole and modified a screw, creating a simple jig that did the job *perfectly*

•••

#diy #diytools #electronics #engineering #learnengineering #workshop #homemadetools

•••

I needed some bare wire to make a power bus for my marble machine motors. After unsuccessfully trying to use wire strippers and a knife, I stumbled upon this method. Using a scrap 3d print, I drilled an extra hole and modified a screw, creating a simple jig that did the job *perfectly*

•••

#diy #diytools #electronics #engineering #learnengineering #workshop #homemadetools

DIY Wire Stripping Jig

‼️This is Truly the Best Wire Stripper in 2024 | ✅️

Hack: DIY Wire Stripper | Basics

This is truly the best wire stripper in 2023

How to make easy wire stripper using just Screw

Best Wire Stripper - Is The Stripmeister Worth It?

Electrician Wire Stripper #SHORTS

I Tried DIY Wire Strippers from YouTube, Which one worked best?

Top 3 Best DIY Knives Wire Stripping

Diy Wire Stripper #shorts

DIY $1 Homemade Wire Stripper - Copper Cord, ROMEX, & Aluminum Cable Cheap Stripping Device Tool

DIY Copper WIRE Stripping Machine | Fantastic

Diy Clean Copper Wires #gsdiymaker #shorts

Fast - Easy Homemade DIY Wire Stripper Jig - Using Harbor Freight Wire Stripper + Wood 12-26 Gauge

The cheapest wire stripper for stripping short lengths of multistrand wires for copper

DIY wire stripper. Simple and SAFE

Copper wire stripping machine. DIY #copper #cable

How to easily make a wire stripper DIY

How to STRIP Copper WIRE | Top 4 DIY Stripping Devices | INCREDIBILE

How to Make a DIY Wire Stripper & Strip Copper Wire for Scrap Metal

How to STRIP Copper WIRE | Top 3 DIY Stripping devices | INCREDIBILE

Simple DIY Wire Stripper

Wire Stripper | Homemade Wire Stripping Jig

This video will make your Life easier. Copper from thin Wires, quickly and easily in just 8 Minutes.

Комментарии

0:00:34

0:00:34

0:03:23

0:03:23

0:01:08

0:01:08

0:04:55

0:04:55

0:00:31

0:00:31

0:15:22

0:15:22

0:00:16

0:00:16

0:18:15

0:18:15

0:12:22

0:12:22

0:00:15

0:00:15

0:02:14

0:02:14

0:00:56

0:00:56

0:00:17

0:00:17

0:19:37

0:19:37

0:05:00

0:05:00

0:00:55

0:00:55

0:00:15

0:00:15

0:00:35

0:00:35

0:12:48

0:12:48

0:13:14

0:13:14

0:17:04

0:17:04

0:02:39

0:02:39

0:08:43

0:08:43

0:08:37

0:08:37