filmov

tv

Coyote Gen 1 CNC update...

Показать описание

Dave updates what went wrong with his road to CNC for the Gen 1 coyote and the head he choose for his personal ride and why he needs a back up plan!

Coyote Gen 1 CNC update...

GEN 1 COYOTE CNC HEAD TEST-PLUS BOSS INTAKE!

Gen 1 Coyote road to CNC part 4

The Road to CNC - Coyote Gen 1!

CNC Ported Coyote 5.0 Cylinder Heads

The Road to CNC Gen 1 Coyote Part 3! Combustion chamber shaping!

Evolution Of The Mustang 5.0L Coyote Engine | Gen 1, Gen 2 & Gen 3

Forged vs Cast Piston Strength!

Mustang vs F-150 Coyote Engine | What's The Difference?

Gen1-2 coyote billet coil cover op1. #cnc #billet

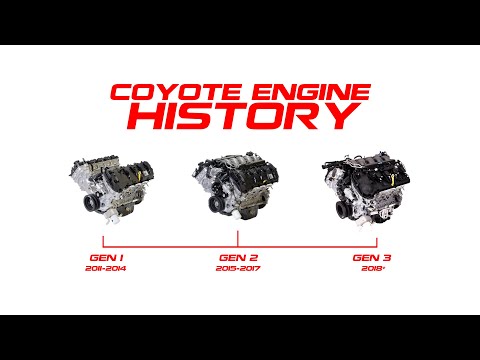

What are the differences in Coyote engine Generations? || Coyote Engine History

Gen 1 coyote head porting done.

Fastest Stock Gen1 Coyote Engine!

The Evolution of The Coyote Engine (Explained)

How A 1600HP Coyote V8 Engine Is Made | Behind The Scenes At FFRE

King Charles security carry guns under their jackets, hidden by fake arms

MMR cooling mod gen 1 coyote engine 5.0

How to Build a Ford Coyote 5.0L Engine

nasty set of big valve cnc ported coyote heads

CNC machining timing cover: Coyote 5.0

Bolt-On Gen 1 Coyote vs Bone Stock 2022 Chevrolet Camaro 1SS

How my 800HP STOCK Gen 1 Coyote Stays Alive!!

Man driving F-150 on its rim with sparks flying out in Reno Nevada

Some Coyote action for you Ford guys 🫡 Our new line of Coyote engines is out now with more to come!...

Комментарии

0:06:54

0:06:54

0:11:45

0:11:45

0:07:09

0:07:09

0:16:45

0:16:45

0:09:27

0:09:27

0:10:16

0:10:16

0:12:20

0:12:20

0:00:44

0:00:44

0:07:14

0:07:14

0:00:06

0:00:06

0:06:58

0:06:58

0:00:12

0:00:12

0:00:31

0:00:31

0:10:44

0:10:44

0:08:56

0:08:56

0:00:47

0:00:47

0:00:15

0:00:15

0:16:41

0:16:41

0:00:33

0:00:33

0:00:26

0:00:26

0:00:34

0:00:34

0:15:47

0:15:47

0:00:17

0:00:17

0:00:16

0:00:16