filmov

tv

Soldering a copper tee for a refrigerator water line | GOT2LEARN

Показать описание

Join my plumbing forum for FREE!

Amazon affiliate links to all the products I used in this video:

TOOLS:

MATERIALS:

DISCLAIMER: Got2Learn is NOT responsible for any damage done to a property of which the plumbing wasn't done by a professional, I do not recommend doing your own plumbing if you are unsure about what you are doing, always hire a LICENSED contractor when doing any type of plumbing so you can be covered by insurances if something does happen, these videos are for entertainment purposes only!

Amazon affiliate links to all the products I used in this video:

TOOLS:

MATERIALS:

DISCLAIMER: Got2Learn is NOT responsible for any damage done to a property of which the plumbing wasn't done by a professional, I do not recommend doing your own plumbing if you are unsure about what you are doing, always hire a LICENSED contractor when doing any type of plumbing so you can be covered by insurances if something does happen, these videos are for entertainment purposes only!

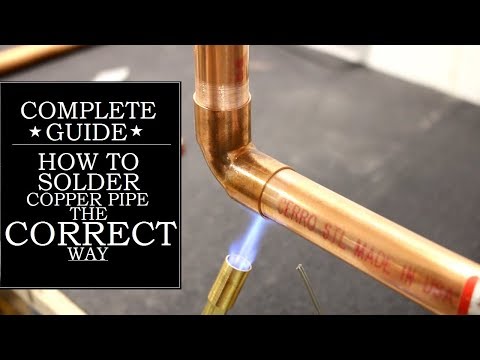

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

Solder Vertical Copper Pipes for Beginners

How To Solder Copper Pipes Like A Pro

How to Solder a Pipe | Ask Richard | Ask This Old House

6 SOLDERING MISTAKES ON COPPER PIPE

How to solder / sweat copper pipe for beginners in 7 easy steps

How To Solder - Plumbing Tips #plumbing #soldering #howto #tutorial

How To Solder Copper Pipes Like A Pro #diy #shorts

Evolution of Amtech Soldering Products - Maxime Dehon - Global Cooling Product Manager

SOLDERING MISTAKE #2 (heat quantity)

Copper Pipe Soldering Tips - #shorts

How to Solder Copper

Soldering Copper Tee #shorts

How To Un Solder a Copper Fitting #shorts #plumbing #plumber #soldering #copper #loop

How To Solder Copper Pipe Like a Pro (Tips & Tricks) | GOT2LEARN

How to solder a LEAD-FREE ball valve | GOT2LEARN

Copper Tee Puller kit

How To Solder Copper Pipe Between 2 Studs With No Movement | GOT2LEARN

Copper Pipe Soldering Tips - #shorts

Soldering A Copper Tee For Water Heater Installation #shorts

How to Solder Copper Pipe LIKE A PRO!

DIY Copper Pipe Leak! How To Fix Like A PRO! #shorts

How to CORRECTLY Solder A Vertical Copper Pipe (Complete Guide) | GOT2LEARN

Soldering A Copper Tee #shorts

Комментарии

0:05:05

0:05:05

0:03:22

0:03:22

0:11:56

0:11:56

0:01:53

0:01:53

0:11:49

0:11:49

0:04:13

0:04:13

0:01:01

0:01:01

0:00:20

0:00:20

0:27:11

0:27:11

0:01:00

0:01:00

0:00:19

0:00:19

0:00:41

0:00:41

0:00:43

0:00:43

0:00:26

0:00:26

0:10:46

0:10:46

0:00:59

0:00:59

0:00:31

0:00:31

0:04:31

0:04:31

0:00:37

0:00:37

0:00:37

0:00:37

0:01:30

0:01:30

0:00:58

0:00:58

0:13:48

0:13:48

0:00:46

0:00:46