filmov

tv

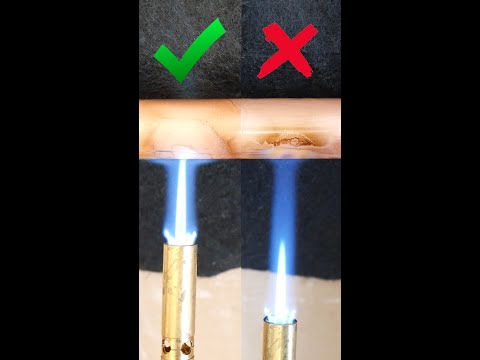

SOLDERING MISTAKE #2 (heat quantity)

Показать описание

Join my plumbing forum for FREE!

Stuff I used in this video (Amazon affiliate links)

Tools:

Stuff I used in this video (Amazon affiliate links)

Tools:

SOLDERING MISTAKE #2 (heat quantity)

5 MISTAKES Beginners Make When Soldering Copper Pipe | GOT2LEARN

SOLDERING MISTAKE #1 (Flux quantity)

SOLDERING MISTAKE #6 (flame position)

6 SOLDERING MISTAKES ON COPPER PIPE

Soldering 1-1/2' Copper Pipe #shorts

SOLDERING MISTAKE #5 (heating location)

How I solder a joint VERTICALLY and why | GOT2LEARN

SOLDERING MISTAKE #4

How to solder a LEAD-FREE ball valve | GOT2LEARN

How to solder copper pipe. #shorts #youtubeshorts #diy

What's the purpose of FLUX when soldering? | GOT2LEARN

SOLDERING MISTAKE #3 (unclean surfaces)

Don't use too much flux when soldering copper pipe, here's why! (Full vid in description b...

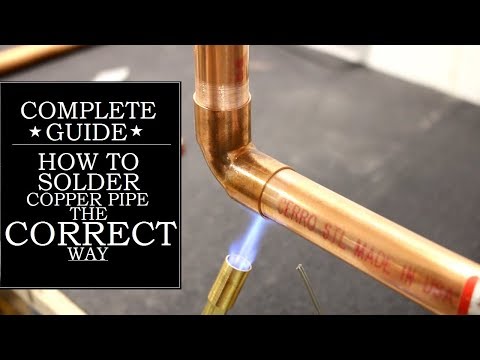

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

How To Solder Copper Pipes Like A Pro #diy #shorts

Watch me ROAST a Solder Joint!

Copper Pipe Soldering Tips - #shorts

The CORRECT Way To Fix A Leaking Joint (UNSOLDERING) | GOT2LEARN

How to solder a vertical copper fitting with no drip #subscribe #youtubeshorts #instagram #plumbing

3 Common Soldering Mistakes (part 1) FLUX #shorts #plumbing #plumber #soldering #fluxo

Lead free fitting solder + flux types | GOT2LEARN

3 Tricks to hold your pipe while soldering! (full video in description box)

How to SOLDER a SHUT-OFF VALVE (sink, toilet etc...) | GOT2LEARN

Комментарии

0:01:00

0:01:00

0:06:05

0:06:05

0:00:57

0:00:57

0:00:52

0:00:52

0:11:49

0:11:49

0:00:20

0:00:20

0:00:45

0:00:45

0:01:00

0:01:00

0:01:00

0:01:00

0:00:59

0:00:59

0:00:23

0:00:23

0:00:57

0:00:57

0:00:44

0:00:44

0:01:00

0:01:00

0:05:05

0:05:05

0:00:20

0:00:20

0:00:35

0:00:35

0:00:37

0:00:37

0:10:38

0:10:38

0:00:28

0:00:28

0:00:42

0:00:42

0:00:44

0:00:44

0:00:47

0:00:47

0:00:58

0:00:58