filmov

tv

How to solder a LEAD-FREE ball valve | GOT2LEARN

Показать описание

Join my plumbing forum for FREE!

Amazon affiliate links to all the products I used in this video:

DISCLAIMER: Got2Learn is NOT responsible for any damage done to a property of which the plumbing wasn't done by a professional, I do not recommend doing your own plumbing if you are unsure about what you are doing, always hire a LICENSED contractor when doing any type of plumbing so you can be covered by insurances if something does happen, these videos are for entertainment purposes only!

Amazon affiliate links to all the products I used in this video:

DISCLAIMER: Got2Learn is NOT responsible for any damage done to a property of which the plumbing wasn't done by a professional, I do not recommend doing your own plumbing if you are unsure about what you are doing, always hire a LICENSED contractor when doing any type of plumbing so you can be covered by insurances if something does happen, these videos are for entertainment purposes only!

How To Solder A LEAD-FREE Ball Valve (Correct Way!!) | GOT2LEARN

Lead solder vs lead-free solder vs silver solder

Using Flux | Soldering Basics | Soldering for Beginners

Lead vs Lead Free Solder - Collin’s Lab Notes #adafruit #collinslabnotes

How to solder a LEAD-FREE ball valve | GOT2LEARN

Desoldering | Soldering Basics | Soldering for Beginners

Best way to solder a wire on PCB #diy #soldering

Leaded vs. Lead-Free Solder Wire: How Tin Content Impacts Your Soldering Results!

Keep it lead free and it’s all good. #stainedglassdiy #leadfreesolder

iFixit's Soldering 101: Beginners Guide

Soldering Crash Course: Basic Techniques, Tips and Advice!

Four Steps to Flawless Wire Joints (How to Solder)

The Difference Between Tin and Lead in Solder Wire – Expert Soldering for Electronic Components

'Apollo' Valves | Lead free bronze two piece ball valves | How to solder

How to solder properly, even with poor tools #soldering #electronics #microscope #arduino

Lead Free Soldering Compared to Lead Soldering | Tips & Methods |

Mastering Rosin Soldering Paste: Lead-Free Flux for Quick and Easy Repairs

SDG #255 SAC305, SAC405, Sc100e, 60/40 Lead/Lead Free Solder Comparison using SolderKing

I hate how dull lead free solder cools, but ultra fine steel wool shines it up pretty well :)

60/40 versus unleaded solder

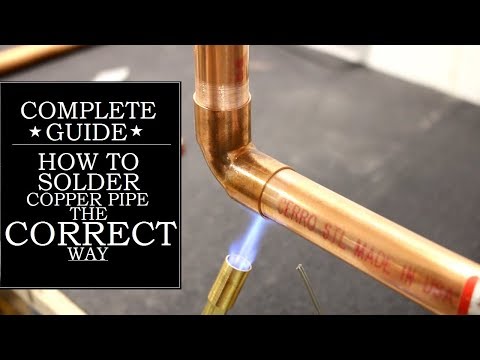

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

Lead free solder/how lead free content impact the best result #tutorial #leadfree #soldering #shorts

How to Solder Lead Free Products

How to solder for beginners

Комментарии

0:06:31

0:06:31

0:14:12

0:14:12

0:03:25

0:03:25

0:00:56

0:00:56

0:00:59

0:00:59

0:03:20

0:03:20

0:00:30

0:00:30

0:00:18

0:00:18

0:00:34

0:00:34

0:06:46

0:06:46

0:16:11

0:16:11

0:11:45

0:11:45

0:00:32

0:00:32

0:05:07

0:05:07

0:01:00

0:01:00

0:07:53

0:07:53

0:00:27

0:00:27

0:24:59

0:24:59

0:00:27

0:00:27

0:10:29

0:10:29

0:05:05

0:05:05

0:00:32

0:00:32

0:02:27

0:02:27

0:00:27

0:00:27