filmov

tv

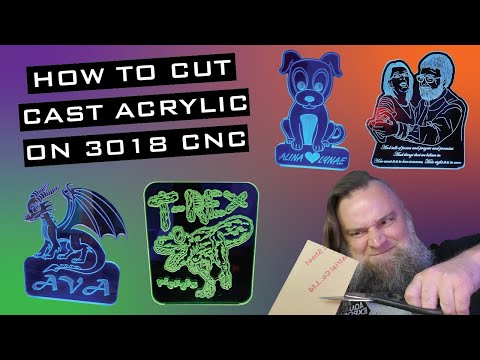

Cutting Acrylic on CNC

Показать описание

I started with the Amana Tool #RC-45711 90° insert carbide v-bit all from our website.

- - - - - - -

#TeamTOOLSTODAY

- - - - - - -

RPM: 18,000

Feed Rate: 40ipm

Plunge Rate: 20ipm

- - - - - - -

I then switched out for the 51441-K 1/16" Spektra™ coated spiral O flute upcut bit to make the holes for the screws to go though.

- - - - - - -

RPM: 18,000

Plunge Rate: 17.5ipm

Spiral ramp down: .125"

- - - - - - -

I then switched out for the 51404-K 1/4" Spektra™ coated spiral O flute upcut bit to cut the remaining profile.

- - - - - - -

RPM: 18,000

Feed Rate: 100ipm

Plunge Rate: 50ipm

Depth of cut: .125"

- - - - - - -

#short #shorts

Tools Used:

STEPCRAFT M.1000 CNC Machine

- - - - - - -

Design Software - Vectric V-Carve Pro -

- - - - - - -

Amana Tool 45771-K Solid Carbide Spektra Extreme Tool Life Coated 30 Degree Engraving 0.005 Tip Width x 1/4 SHK x 2-1/4 Inch Long Signmaking Router Bit

- - - - - - -

HOW TO MILL plexiglass & acrylics with WATTSAN CNC router

How To Cut Clear Acrylic On A CNC Router and CO2 Laser | Laguna Tools

Acrylic Speeds & Feeds for Shapeoko - #MaterialMonday

Cutting Acrylic on CNC

Cast Acrylic Machining Guide for the Nomad CNC - #MaterialMonday

Best Bits and Techniques for Cutting Acrylic - Ask a Tech #57

3018 CNC. 10mm extruded acrylic

Cutting of 10 mm acrylic on CNC Router.

Stepmores cnc router 1325MF spindle+knife+V

Polycarbonate (Lexan) quick cutout on the new CNC

How to Make: CNC LED Holiday Sign

Engraving/Cutting Acrylic with a CNC

Testing 6 Different CNC Bits to Cut/Mill Cast Acrylic with my 3018 PROVer

Tips for Cutting Acrylic on 3018 CNC - Type of Acrylic, Tape Method, Job Home with Paper Method

Acrylic Cutting: CNC Router vs Laser - Which is Best? | Trotec Laser

CNC Plastic Cutting with Amana Tool Spektra Router Bit | ToolsToday

How to avoid a poor finish when cutting acrylic on a CNC Router

Test cutting acrylic CNC 3018 | speed and feedrate

How to Cut Plexiglass & Acrylics with CNC | Scientific & Polished Method

How To Cut Cast Acrylic on 3018 CNC Sainsmart PROVer using Carbide Create & Off line Controller

Best CNC Bit for Plastic | O- Flute | CNC Router Bits

Making Edge-Lit Acrylic Signs - Drag Engraved vs Machined Examples

CNC Acrylic with 3018 - Cutting and Engraving a Raspberry Pi Case

Cutting 1/4' Acrylic

Комментарии

0:02:36

0:02:36

0:04:39

0:04:39

0:05:05

0:05:05

0:00:56

0:00:56

0:03:22

0:03:22

0:07:27

0:07:27

0:00:27

0:00:27

0:01:01

0:01:01

0:00:45

0:00:45

0:00:28

0:00:28

0:06:12

0:06:12

0:19:31

0:19:31

0:08:00

0:08:00

0:08:46

0:08:46

0:04:33

0:04:33

0:01:06

0:01:06

0:03:12

0:03:12

0:03:11

0:03:11

0:07:05

0:07:05

0:13:38

0:13:38

0:05:44

0:05:44

0:08:35

0:08:35

0:05:15

0:05:15

0:00:59

0:00:59