filmov

tv

Best Bits and Techniques for Cutting Acrylic - Ask a Tech #57

Показать описание

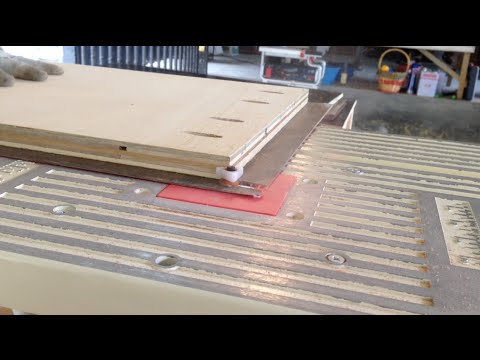

Some useful tips for cutting plastic (acrylic) using a router or CNC machine are discussed in this video.

Some Tips:

Freeze material for an hour before cutting

Use ice water in spray bottle to cool cutting

Larger diameter bits are better at cutting cleanly

Special acrylic cutting bits perform well

Acrylic come as cast or extruded. Cast cuts better!

You can use the flame method on the edge of cuts to smooth them over.

--------------------------------------------------------

Your Name: Petur

Title of Question: CNC

The Question: Hi, I´m using router table and hand held router to cut acrylic mostly 5mm, what bit is best for good result (smooth edges).

Regards, Petur.

--------------------------------------------------------

Links to pages show in video:

Best Bits and Techniques for Cutting Acrylic - Ask a Tech #57

All Materials Found Here (c) The Guru Brew Tech Web Show

Some Tips:

Freeze material for an hour before cutting

Use ice water in spray bottle to cool cutting

Larger diameter bits are better at cutting cleanly

Special acrylic cutting bits perform well

Acrylic come as cast or extruded. Cast cuts better!

You can use the flame method on the edge of cuts to smooth them over.

--------------------------------------------------------

Your Name: Petur

Title of Question: CNC

The Question: Hi, I´m using router table and hand held router to cut acrylic mostly 5mm, what bit is best for good result (smooth edges).

Regards, Petur.

--------------------------------------------------------

Links to pages show in video:

Best Bits and Techniques for Cutting Acrylic - Ask a Tech #57

All Materials Found Here (c) The Guru Brew Tech Web Show

Best Bits and Techniques for Cutting Acrylic - Ask a Tech #57

The Best Router Bits For Beginners

The Best Router Bits For Wording - Which Router Bits Are For Which Job

CNC Router Bits Explained: The Best Bit To Use

Which Impact Driver Bit is Best? Let's find out! Phillips #2 Showdown

Best Slab Flattening Router Bit of 2024 [Surfacing Router Bit]

Best Drill Bits For Metal, Stainless Steel 2021

Best Drill Bit to Cut Circles on Wood 2021

Roughing Bit | Best Bit for Pocketing | CNC Router Bits

Best Surfacing Router bit of 2021 II 5 Best Surfacing Router bit of 2021

What is the Best Bit Holder? Wera Impaktor, Makit XPS, Milwaukee Shockwave, Wiha, and More!

Best drill bit for hardened steel, how to drill through a broken bolt amazing results

Best Star (Torx) Bit Brand? Milwaukee, DeWalt, Makita, Ryobi, Wera, Wiha, Irwin, Bosch, Bauer

Best Router Bit for Trimming Laminate Veneer

How to Choose the Best Bits for Your CNC

Master Joinery Techniques: Explore the 7 Best Tongue And Groove Router Bits

Best CNC Bit for Plastic | O- Flute | CNC Router Bits

Best way to use a Diamond Tile Drill Bit with a cordless drill - TOO EASY!

The Makita Bit Piece. How best to use E6 bits in a JDM (JIS) Makita chuck. What you need to know.

Best Drill Bit Set? Hilti vs Milwaukee, DeWalt, Bosch, Bauer, Lenox, Irwin

Best Drill Bit Set? $11 vs $200? Let’s Settle This!

6 Best Router Bits Demonstration

Best 4 Router Bits For Beginners

These Magnetic Drill Bits can help you get the best grip for drilling!🔥🛠️ #tools #besttools

Комментарии

0:07:27

0:07:27

0:08:26

0:08:26

0:07:09

0:07:09

0:11:14

0:11:14

0:12:28

0:12:28

0:04:26

0:04:26

0:00:11

0:00:11

0:00:13

0:00:13

0:07:49

0:07:49

0:04:32

0:04:32

0:17:48

0:17:48

0:01:22

0:01:22

0:13:35

0:13:35

0:06:00

0:06:00

0:06:43

0:06:43

0:09:54

0:09:54

0:05:44

0:05:44

0:03:07

0:03:07

0:08:54

0:08:54

0:16:12

0:16:12

0:16:28

0:16:28

0:03:15

0:03:15

0:10:59

0:10:59

0:00:27

0:00:27