filmov

tv

HOW TO SOLDER COPPER PIPE - END FEED - REALISTIC Plumbing Tips

Показать описание

How to solder copper pipe in the real world. Not on some vice on the desk but under it. In a hard to reach position. How to use flux and clean pipe, solder and a torch. How to use a heat matt and a cooling rag to make a water tight seal.

***VISIT OUR SPONSORS***

***VISIT OUR SPONSORS***

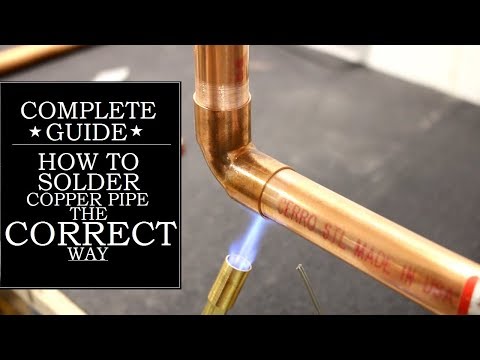

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

How To Solder Copper Pipe (Complete Guide) Plumbing 101

How To Solder Copper Pipe Like a Pro (Tips & Tricks) | GOT2LEARN

How To Solder Copper Pipes Like A Pro

Solder Vertical Copper Pipes for Beginners

6 SOLDERING MISTAKES ON COPPER PIPE

How To Solder Copper Pipes | The Home Depot with @thisoldhouse

How To Solder Copper Pipes Like A Pro #diy #shorts

Welding Basics: Everything You NEED To Know Before You Start

How to Solder a Pipe | Ask Richard | Ask This Old House

Copper Pipe Soldering Tips - #shorts

How to CORRECTLY Solder A Vertical Copper Pipe (Complete Guide) | GOT2LEARN

UNMISSABLE TIP How To Solder Copper Pipe Without Runs

How to Solder Copper Pipe in a Wall (Complete Guide) | GOT2LEARN

How to Solder Copper Pipe

How to solder / sweat copper pipe for beginners in 7 easy steps

How to solder a hole in a copper pipe. Plumber's Tricks. DIY

How To Solder - Plumbing Tips #plumbing #soldering #howto #tutorial

How To Solder Copper Pipe Between 2 Studs With No Movement | GOT2LEARN

How to Solder Copper Pipe (Important Tips!!) -- by Home Repair Tutor

SOLDERING MISTAKE #2 (heat quantity)

7 STEPS TO SOLDER COPPER PIPE

HOW TO SOLDER COPPER PIPE | Real World Plumbing #howto #plumbing #asmr

How To Un Solder a Copper Fitting #shorts #plumbing #plumber #soldering #copper #loop

Комментарии

0:05:05

0:05:05

0:05:54

0:05:54

0:10:46

0:10:46

0:11:56

0:11:56

0:03:22

0:03:22

0:11:49

0:11:49

0:03:57

0:03:57

0:00:20

0:00:20

0:02:54

0:02:54

0:01:53

0:01:53

0:00:19

0:00:19

0:13:48

0:13:48

0:08:26

0:08:26

0:15:30

0:15:30

0:01:15

0:01:15

0:04:13

0:04:13

0:02:35

0:02:35

0:01:01

0:01:01

0:04:31

0:04:31

0:09:46

0:09:46

0:01:00

0:01:00

0:11:06

0:11:06

0:00:34

0:00:34

0:00:26

0:00:26