filmov

tv

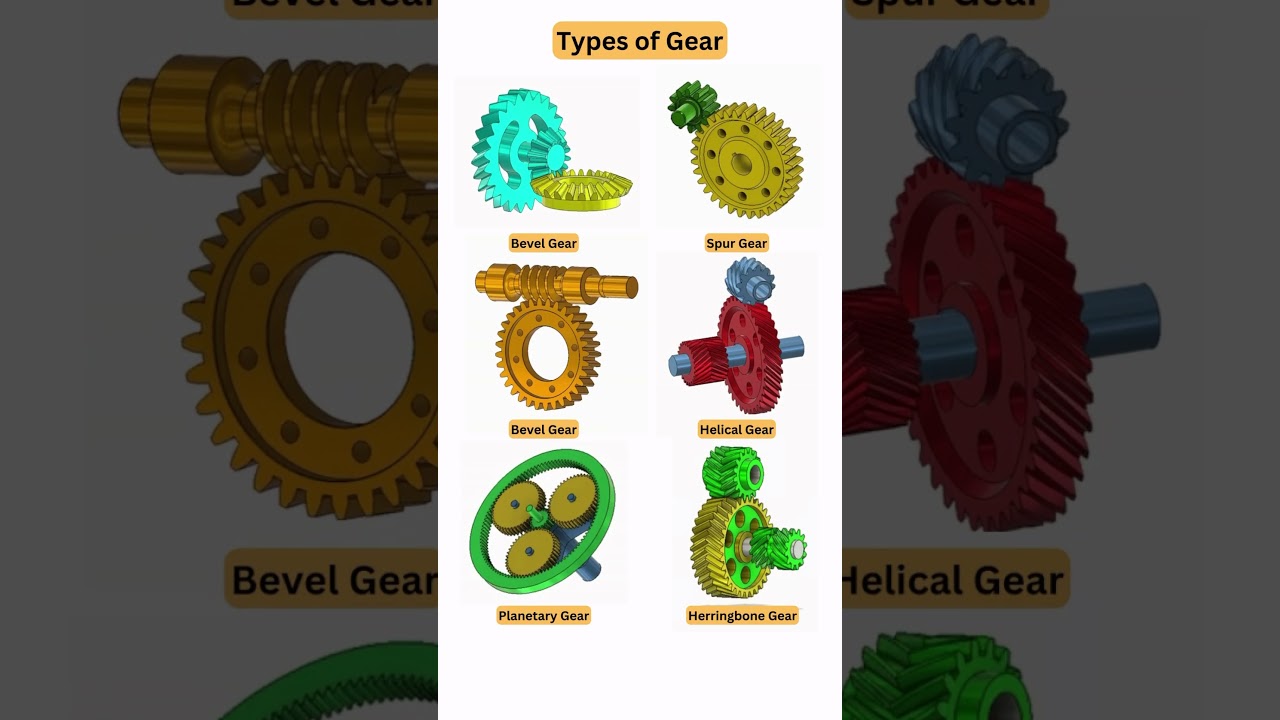

1) Bevel 2)Spur 3)Worm 4)Helical 5)Planetary 6)Herringbone #3danimation #cad #gear #engineering #3d

Показать описание

1) Bevel Gear: Bevel gears have cone-shaped teeth and are used to transmit motion and power between intersecting shafts. They are often used in applications where the input and output shafts are not parallel, such as in differentials in vehicles.

2) Spur Gear: Spur gears are the most common type of gear. They have straight teeth that run parallel to the gear axis. Spur gears transmit motion and power between parallel shafts and are found in various machines and mechanical systems.

3) Worm Gear: Worm gears consist of a worm (a screw-like gear) and a worm wheel (a gear with helical teeth). They provide high gear reduction ratios and are used when you need to achieve a large speed reduction in a compact space.

4) Helical Gear: Helical gears have angled teeth that are not parallel to the gear axis. This design helps reduce noise and vibration compared to spur gears. They are often used in applications that require smoother motion transmission.

5) Planetary Gear: Planetary gears, also known as epicyclic gears, consist of a central sun gear, planet gears that rotate around the sun gear, and an outer ring gear that meshes with the planet gears. They offer high gear reduction ratios and are commonly used in automatic transmissions and various industrial machinery.

6) Herringbone Gear: Herringbone gears, also called double helical gears, consist of two helical gears with opposite helix angles placed side by side. This design cancels out axial thrust forces, making them suitable for high-load applications where axial forces need to be minimized.

2) Spur Gear: Spur gears are the most common type of gear. They have straight teeth that run parallel to the gear axis. Spur gears transmit motion and power between parallel shafts and are found in various machines and mechanical systems.

3) Worm Gear: Worm gears consist of a worm (a screw-like gear) and a worm wheel (a gear with helical teeth). They provide high gear reduction ratios and are used when you need to achieve a large speed reduction in a compact space.

4) Helical Gear: Helical gears have angled teeth that are not parallel to the gear axis. This design helps reduce noise and vibration compared to spur gears. They are often used in applications that require smoother motion transmission.

5) Planetary Gear: Planetary gears, also known as epicyclic gears, consist of a central sun gear, planet gears that rotate around the sun gear, and an outer ring gear that meshes with the planet gears. They offer high gear reduction ratios and are commonly used in automatic transmissions and various industrial machinery.

6) Herringbone Gear: Herringbone gears, also called double helical gears, consist of two helical gears with opposite helix angles placed side by side. This design cancels out axial thrust forces, making them suitable for high-load applications where axial forces need to be minimized.

Комментарии

0:00:05

0:00:05

0:15:45

0:15:45

0:03:12

0:03:12

0:01:12

0:01:12

0:14:36

0:14:36

0:10:59

0:10:59

0:12:49

0:12:49

0:01:05

0:01:05

0:01:00

0:01:00

0:17:52

0:17:52

0:00:18

0:00:18

0:01:00

0:01:00

0:05:42

0:05:42

0:08:57

0:08:57

0:02:31

0:02:31

0:09:59

0:09:59

0:18:37

0:18:37

0:08:30

0:08:30

0:03:05

0:03:05

0:09:28

0:09:28

0:05:42

0:05:42

0:00:39

0:00:39

0:02:51

0:02:51

0:01:36

0:01:36