filmov

tv

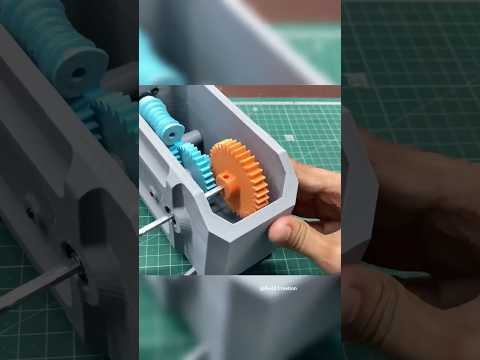

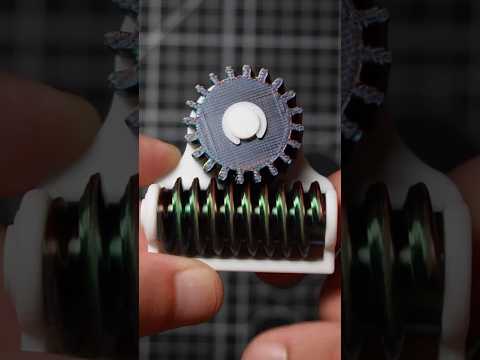

3D Printed WORM GEAR - Can u Really Use Them? (PLA vs PETG vs ABS)

Показать описание

Can u really use 3D printed worm gears or they self-destruct themselves? In this video, we run dry and lubricated tests at low, medium, and high speed. We test most common 3D printing materials such as PLA, ABS and, PETG. I use only high-quality filaments.

________________________________________________________________

________________________________________________________________

All that u need more:

________________________________________________________________

________________________________________________________________

________________________________________________________________

All that u need more:

________________________________________________________________

3D Printed WORM GEAR - Can u Really Use Them? (PLA vs PETG vs ABS)

3D printer UP! Plus2 worm gear

3d Printed NEMA 17 Worm gear box 60:1

Which 3D Printed Gear is Best?

High Locking Torque Worm gearbox | 3D printed #gearbox #gear #3dprinted #motor

Awesome 3D Printed Toys

3D Printed Motor Driven Jack Screw

Logan Lathe, 3d printed gears!

3D printed WormGearbox

Worm Gear Review - Quality Control?

This is why worm gears are so cool...

3D printed worm gears designed in Fusion 360

3D printed worm gear mechanism

I tried to find the Strongest Filament Extruder.

3D Printed Worm Gear Drive

Strong DIY 3d Printed Worm Gearbox - Test by Screwdriver

a 3d printed worm gear system - it's so noisy!

Worm Drive Gears 3D Print

3D printed worm and worm gear

Satisfying 3D printed Worm Gear #shorts #diy #3dprinting

My 3D Printed Worm Gear 🐛 #shorts

3d printed worm gear demo

How to model Worm Gears (Gears pt 7/?)

Worm Gear Davinci 3D Print - Split Print Glued Together - Video #027

Комментарии

0:12:49

0:12:49

0:00:41

0:00:41

0:00:15

0:00:15

0:18:00

0:18:00

0:00:44

0:00:44

0:20:42

0:20:42

0:00:45

0:00:45

0:11:22

0:11:22

0:01:38

0:01:38

0:06:03

0:06:03

0:03:12

0:03:12

0:15:52

0:15:52

0:00:12

0:00:12

0:20:32

0:20:32

0:00:15

0:00:15

0:00:16

0:00:16

0:00:31

0:00:31

0:00:18

0:00:18

0:00:12

0:00:12

0:00:35

0:00:35

0:00:16

0:00:16

0:00:16

0:00:16

0:18:37

0:18:37

0:07:44

0:07:44