filmov

tv

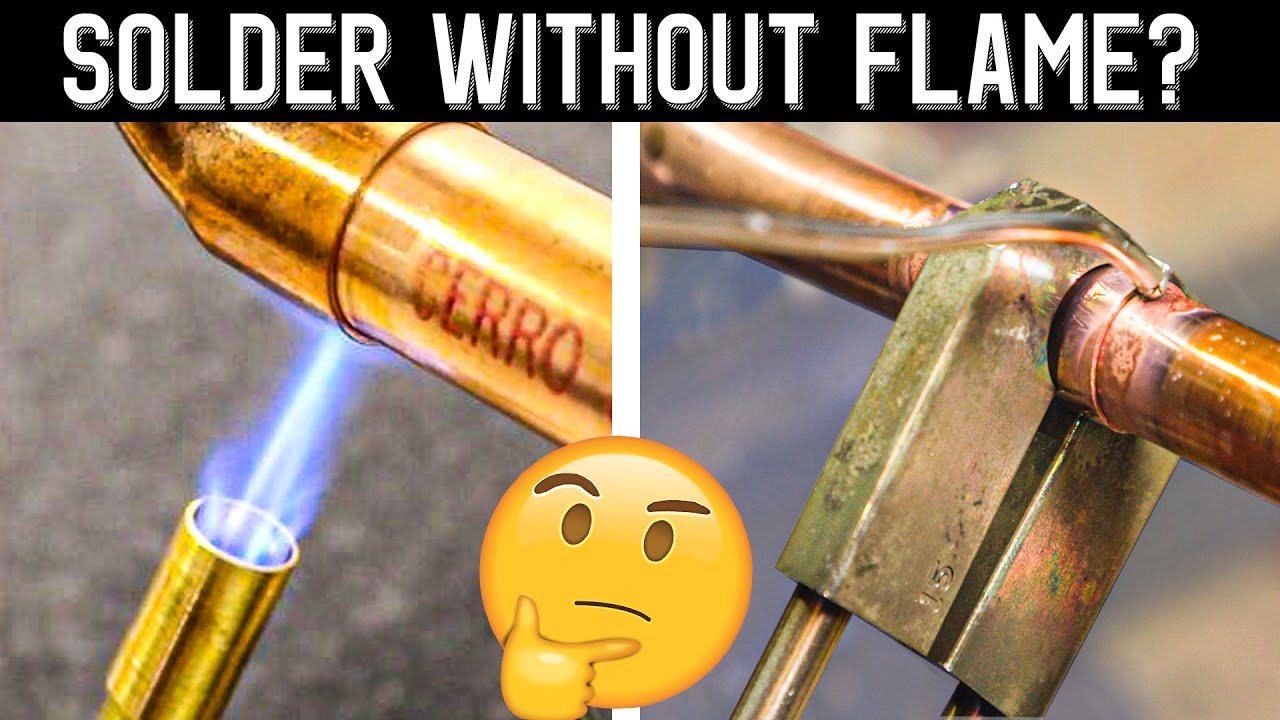

Solder copper pipe WITHOUT flame or blow torch

Показать описание

Today I show you how to solder copper pipe WITHOUT a naked flame or a blow torch.

Ever wondered if you can solder copper pipe WITHOUT a blow torch or naked flame? Ever worried about buring down the house whilst fixing that copper pipe leak? Well this week I review the Pipemaster Professional Plumbing Tool. It's 'OK'....but I'll leave it up to you to decide. We solder straight couplings and elbows. We also solder capillary fittings too.

#Plumbing #Plumber #PlumbingAdvice

Ever wondered if you can solder copper pipe WITHOUT a blow torch or naked flame? Ever worried about buring down the house whilst fixing that copper pipe leak? Well this week I review the Pipemaster Professional Plumbing Tool. It's 'OK'....but I'll leave it up to you to decide. We solder straight couplings and elbows. We also solder capillary fittings too.

#Plumbing #Plumber #PlumbingAdvice

Solder copper pipe WITHOUT flame or blow torch

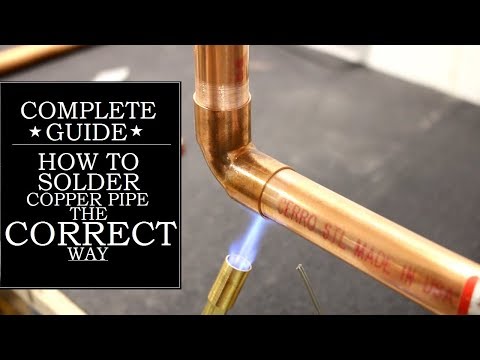

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

How to Solder Copper Pipe without a flame UK

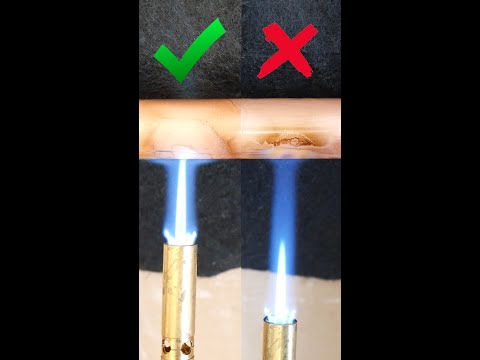

6 SOLDERING MISTAKES ON COPPER PIPE

SOLDERING MISTAKE #2 (heat quantity)

How to Solder a Pipe | Ask Richard | Ask This Old House

How To Solder Copper Pipes Like A Pro #diy #shorts

Connect Copper Pipe Without Solder

Solder Vertical Copper Pipes for Beginners

How To Solder Copper Pipes Like A Pro

How To Solder Copper Pipe Like a Pro (Tips & Tricks) | GOT2LEARN

How To Solder Copper Pipe (Complete Guide) Plumbing 101

SOLDERING MISTAKE #6 (flame position)

UNMISSABLE TIP How To Solder Copper Pipe Without Runs

Cooling copper pipe welding process- Good tools and machinery make work easy

Can you SOLDER a copper joint with a 5$ MINI-TORCH? | GOT2LEARN

Brazing copper

Soldering Copper Pipes With Water in Them (7 Solutions) | GOT2LEARN

How To Solder Copper Pipes | The Home Depot with @thisoldhouse

How to solder copper without using gas? You will be amazed with this homemade tool

Solder copper pipes without an open flame using Alesco induction heaters

How to Solder Copper To Copper with a Propane Torch and Hide the Solder Joint

Soldering 1-1/2' Copper Pipe #shorts

How to solder copper pipe. #shorts #youtubeshorts #diy

Комментарии

0:15:07

0:15:07

0:05:05

0:05:05

0:05:07

0:05:07

0:11:49

0:11:49

0:01:00

0:01:00

0:01:53

0:01:53

0:00:20

0:00:20

0:01:19

0:01:19

0:03:22

0:03:22

0:11:56

0:11:56

0:10:46

0:10:46

0:05:54

0:05:54

0:00:52

0:00:52

0:08:26

0:08:26

0:00:09

0:00:09

0:02:13

0:02:13

0:00:30

0:00:30

0:06:05

0:06:05

0:03:57

0:03:57

0:10:19

0:10:19

0:00:20

0:00:20

0:02:17

0:02:17

0:00:20

0:00:20

0:00:23

0:00:23