filmov

tv

Common Beginner Mistakes | Welding

Показать описание

-

-

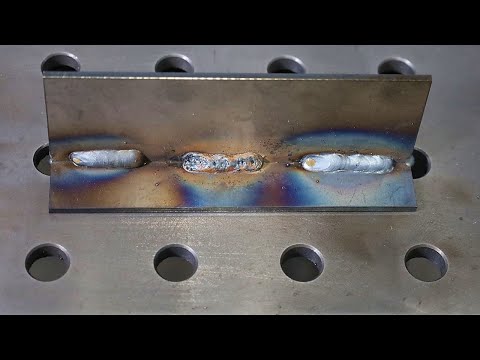

I'm going to try to demonstrate some of the most common problems or mistakes that beginning arc welders encounter. One is which the arc will not start, or the arc rod sticks. Neither is cause for panic, and is usually the result of one or two things. Either your voltage is set too low or the rod you're using for the job is too big. A third possibility is that your material is dirty. That is it might be too rusty, painted or, in some other ways, interfering with the electrical contact with the table. Here you can see we have no flow of electricity whatsoever and, therefore, it's impossible to strike an arc. A less common problem, but one you may encounter in any case is that your voltage is set too high or that your rod is too small for the job that you've selected. As you can see here, the rod fails to penetrate. Metal splatters everywhere, and otherwise prevents you from making a good weld. A good rule of thumb is to check your manufacturer's guidelines to see which rod is recommended for what thickness of metal and what range of amperage. Those ranges, high and low, should never be exceeded.

-

I'm going to try to demonstrate some of the most common problems or mistakes that beginning arc welders encounter. One is which the arc will not start, or the arc rod sticks. Neither is cause for panic, and is usually the result of one or two things. Either your voltage is set too low or the rod you're using for the job is too big. A third possibility is that your material is dirty. That is it might be too rusty, painted or, in some other ways, interfering with the electrical contact with the table. Here you can see we have no flow of electricity whatsoever and, therefore, it's impossible to strike an arc. A less common problem, but one you may encounter in any case is that your voltage is set too high or that your rod is too small for the job that you've selected. As you can see here, the rod fails to penetrate. Metal splatters everywhere, and otherwise prevents you from making a good weld. A good rule of thumb is to check your manufacturer's guidelines to see which rod is recommended for what thickness of metal and what range of amperage. Those ranges, high and low, should never be exceeded.

Комментарии