filmov

tv

5 Welding Problems Fixed: Welding Basics for Beginners

Показать описание

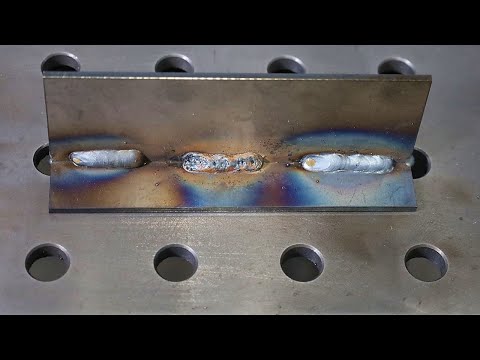

A scenic tour of 5 common welding defects, their cause and how to fix them.

There are many welding defects, and the ability to identify and correct them will make you a better welder. In this video, we go over the following:

0:00 Intro

0:31 Lack of Fusion

2:30 Weld Profile

3:35 Porosity

5:00 Undercut

6:03 Cracking

****Affordable self-paced welding courses taught by me****

***Gear you might want***

(These are affiliate links that provide a small commission to support the making of these videos)

***More Videos you Might Like***

Some of the links on this page are affiliate links which provide a small commission from sales to help support this channel and make these videos possible. Thanks for your support!

There are many welding defects, and the ability to identify and correct them will make you a better welder. In this video, we go over the following:

0:00 Intro

0:31 Lack of Fusion

2:30 Weld Profile

3:35 Porosity

5:00 Undercut

6:03 Cracking

****Affordable self-paced welding courses taught by me****

***Gear you might want***

(These are affiliate links that provide a small commission to support the making of these videos)

***More Videos you Might Like***

Some of the links on this page are affiliate links which provide a small commission from sales to help support this channel and make these videos possible. Thanks for your support!

5 Welding Problems Fixed: Welding Basics for Beginners

6013 Stick Welding Problem Fixed

How NOT TO Weld: Most Common MIG Welding Mistakes

WELDING DEFECTS- Porosity, cracks, undercut, lack of fusion, arc strike, underfill, LOF

Fix This MIG Welding Problem

5 MIG Welding Mistakes I Made as a Beginner

Troubleshooting Common Industrial MIG Welding Problems

Stick Welding: #1 Beginner Mistake and How to Fix It

MIG Welding Quick Tip - How to Fix Excessive Spatter - MIG Welding from Eastwood

Stop welding poor quality work. If you only know this technique.

WELDING DEFECTS | WELDING IMPERFECTION | CRACK | POROSITY | UNDERCUT | SPATTER | SLAG INCLUSION

Argon arc welding machine. Welder's aid. Fixer accessories

stop bad welding !!! three welding techniques position 2f

Why Pipeliners Do NOT use Auto Darkening Welding Hoods (Fixed vs Auto-Darkening Welding Lens)

How To Avoid Contact Tip Issues When MIG Welding

Help! I Can't See When I'm Welding!

beginner welder mistakes, secret technique of welding galvanized thin metal

Welding goggles

MIG Welding Basics For Beginners

thin pipe welding secrets, why didn't the welder tell me this welding secret

secret trick stick welding , why no welders talk about this

amazing welding method of Pakistani welder #welding #shorts

rarely known by the welder about damage to the welding cable

Learn Perfect Flux Core Welds In 10 Mins | Gasless Flux Core Welding For Beginners Tips And Tricks |

Комментарии

0:07:28

0:07:28

0:05:34

0:05:34

0:16:44

0:16:44

0:08:11

0:08:11

0:04:42

0:04:42

0:08:27

0:08:27

0:07:21

0:07:21

0:06:06

0:06:06

0:00:50

0:00:50

0:03:26

0:03:26

0:10:42

0:10:42

0:00:22

0:00:22

0:03:50

0:03:50

0:03:02

0:03:02

0:01:22

0:01:22

0:10:08

0:10:08

0:02:20

0:02:20

0:00:19

0:00:19

0:14:40

0:14:40

0:02:34

0:02:34

0:00:31

0:00:31

0:00:34

0:00:34

0:04:00

0:04:00

0:09:34

0:09:34