filmov

tv

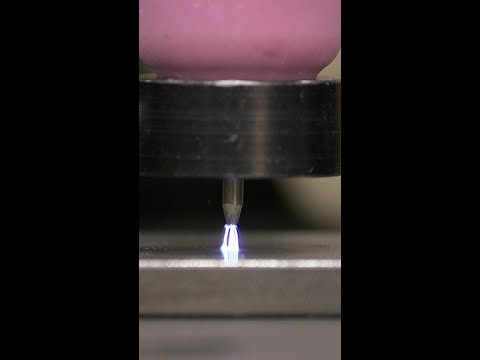

TIG Welding Root Techniques | Elevate Your TIG Skills!

Показать описание

In this in-depth welding tutorial, embark on a journey to master a diverse skill set in TIG welding, covering a wide array of essential techniques that every tig welder should know. Whether you're a seasoned pro or just starting on your welding path, this video is your comprehensive guide to honing your TIG welding skills to perfection.

Skills Explored:

Backfeed Root Technique: I'll delve into the art of achieving pristine root welds using the backfeed technique, ensuring strong, clean, and dependable connections. Learn the nuances of this technique and avoid common pitfalls.

Keyhole Technique: The Keyhole Technique is revealed in all its glory. Discover how to create seamless welds with this advanced method, and understand its applications.

Freehand Welding: Learn the finesse of welding without the aid of guides or fixtures. Freehand welding is a skill that allows for greater flexibility and adaptability in various welding scenarios.

Walking the Cup: Explore the "Walking the Cup" technique, a popular method for maintaining consistent and controlled weld beads. Understand the mechanics and nuances of cup walking, enhancing the quality of your welds.

Fixing Bad Pipe Prep: Not every welding project begins with a perfectly prepped pipe. We show you how to deal with less-than-ideal pipe conditions. This troubleshooting guide is invaluable for welders working in less-than-ideal conditions.

Elevate Your Welding Game:

By the end of this video, you'll have a profound understanding of these essential TIG welding techniques and the confidence to apply them to a variety of welding projects. Whether it's perfecting your root welds, achieving seamless keyhole welds, mastering freehand welding, or walking the cup like a pro, I got you covered.

None of these videos are recorded in a fancy shop surrounded by sponsorship banners!

My videos are recorded at working sites in various locations and welding positions.

90% of my welding projects in videos are x-rayed, and if you like to see hands-on projects, welcome!

If you liked this video please give it a thumbs up, share it, subscribe, and click the bell.

It doesn’t cost you anything but massively helps my YouTube channel. Thank you.

Support this channel with 🔔 Subscribe and 👍 Like!

🌐 Stay Connected & Learn More:

Skills Explored:

Backfeed Root Technique: I'll delve into the art of achieving pristine root welds using the backfeed technique, ensuring strong, clean, and dependable connections. Learn the nuances of this technique and avoid common pitfalls.

Keyhole Technique: The Keyhole Technique is revealed in all its glory. Discover how to create seamless welds with this advanced method, and understand its applications.

Freehand Welding: Learn the finesse of welding without the aid of guides or fixtures. Freehand welding is a skill that allows for greater flexibility and adaptability in various welding scenarios.

Walking the Cup: Explore the "Walking the Cup" technique, a popular method for maintaining consistent and controlled weld beads. Understand the mechanics and nuances of cup walking, enhancing the quality of your welds.

Fixing Bad Pipe Prep: Not every welding project begins with a perfectly prepped pipe. We show you how to deal with less-than-ideal pipe conditions. This troubleshooting guide is invaluable for welders working in less-than-ideal conditions.

Elevate Your Welding Game:

By the end of this video, you'll have a profound understanding of these essential TIG welding techniques and the confidence to apply them to a variety of welding projects. Whether it's perfecting your root welds, achieving seamless keyhole welds, mastering freehand welding, or walking the cup like a pro, I got you covered.

None of these videos are recorded in a fancy shop surrounded by sponsorship banners!

My videos are recorded at working sites in various locations and welding positions.

90% of my welding projects in videos are x-rayed, and if you like to see hands-on projects, welcome!

If you liked this video please give it a thumbs up, share it, subscribe, and click the bell.

It doesn’t cost you anything but massively helps my YouTube channel. Thank you.

Support this channel with 🔔 Subscribe and 👍 Like!

🌐 Stay Connected & Learn More:

Комментарии

0:11:31

0:11:31

0:16:10

0:16:10

0:00:14

0:00:14

0:00:30

0:00:30

0:00:20

0:00:20

0:10:06

0:10:06

0:00:12

0:00:12

0:00:22

0:00:22

0:12:40

0:12:40

0:09:58

0:09:58

0:15:38

0:15:38

0:11:05

0:11:05

0:00:12

0:00:12

0:00:16

0:00:16

0:00:40

0:00:40

0:00:16

0:00:16

0:01:01

0:01:01

0:00:15

0:00:15

0:00:12

0:00:12

0:10:07

0:10:07

0:00:08

0:00:08

0:00:24

0:00:24

0:00:18

0:00:18

0:00:13

0:00:13