filmov

tv

How To Splice | Practical Wiring Demonstration [GOLD WEBINAR]

Показать описание

Splicing a single wire out to multiple wires is something that must be done multiple times for every harness build, and there are always questions about the best way to go about it. In this webinar we'll look at how we size the splice to use, the required tooling, where the splice should be located in the harness, and perform a practical demonstration of the process.

Due to the current global situation we though over the next few weeks we'd help keep you guys out there entertained and release some of these otherwise webinars to you for free to help pass the time.

Want to watch the members-only webinar on Engine Build Considerations or Engine Failure Analysis along with over 230 other lessons on engine building, tuning, and wiring topics? Grab the course above and we'll include 3 months of free access in the purchase price.

#highperformanceacademy #motorsportwiring #splicing #splice #dontletthesmokeout #goldwebinar #motorsportwiring

How To Splice | Practical Wiring Demonstration [GOLD WEBINAR]

Ask Leroy! Ep. 25 | How to Splice Rope

How To Fusion Splice Fiber Optic Cable - Animated

How To splice Optical Fiber Cable Using Fujikura Fusion Splicing Machine(Practical & Demo)

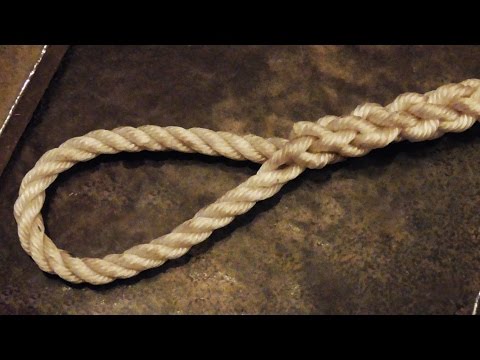

'Easy To Follow' - How To Tie An Eye Splice In 3 Strand Rope

How to Splice Three-Strand Rope | Making an Eye-Splice in Nylon Rope

Learn How To Splice Fiber Cable|| Complete Practical || Urdu/Hindi

How to Splice a broken Optical Fiber cable - Real Demonstration

How to splice 3 strand rope easily. Splicing a loop or eye in polysteel lobster / crab pot rope.

How to splice LeadCore! Carp fishings tips!

splicing treannig fiber optic cable || how to splice || where use splice || practical splicing

Learn How to Splice a Rope in 3 MINUTES

End Splice - AB Marlinespike Seamanship Practical Demonstration

How to Splice fiber optical cable||Practical step to step

How to Splice Double Braid Line [LINKS TO FIDS👇] | BoatUS

Eye Splice - AB Marlinespike Seamanship Practical Demonstration

How to Splice Thermostat / Control Wire with the 'NASA Splice'

how to splice wire rope#shorts

3 Ways to CORRECTLY Splice Electrical Wires

How to splice wires - how to solder, how to crimp, wire connectors

Traditional Rigging, Part 7: Making a Wire Splice

How to splice puzzle ring#Interesting#Practical#Convenient#Shorts

[How to] Dyneema Eye Splice | Sailing Wisdom

Ring Splice Crown Method - Splicing a Rope onto a Ring Using the Crown Knot Method

Комментарии

0:47:13

0:47:13

0:08:26

0:08:26

0:02:13

0:02:13

0:04:32

0:04:32

0:05:42

0:05:42

0:06:27

0:06:27

0:09:24

0:09:24

0:13:59

0:13:59

0:05:04

0:05:04

0:04:45

0:04:45

0:17:25

0:17:25

0:03:16

0:03:16

0:05:51

0:05:51

0:07:01

0:07:01

0:05:52

0:05:52

0:03:49

0:03:49

0:17:07

0:17:07

0:00:14

0:00:14

0:14:22

0:14:22

0:10:01

0:10:01

0:29:25

0:29:25

0:00:16

0:00:16

![[How to] Dyneema](https://i.ytimg.com/vi/UpkqJ4GRfSg/hqdefault.jpg) 0:18:18

0:18:18

0:11:50

0:11:50