filmov

tv

How to Resume an Unfinished/Failed 3D Print! (EASY FIX!)

Показать описание

Thank you to Bellroy for sponsoring this video!

Have you ever had a print run out of filament, or stop due to a power outage? Well here's an easy fix!

Support the channel on Patreon!:

~~~ My Socials ~~~

Have you ever had a print run out of filament, or stop due to a power outage? Well here's an easy fix!

Support the channel on Patreon!:

~~~ My Socials ~~~

How to Resume an Unfinished/Failed 3D Print! (EASY FIX!)

HOW TO: Resume a failed 3D print!

HOW TO SHOW AN UNFINISHED DEGREE ON YOUR RESUME IF YOU DIDNT GRADUATE COLLEGE OR UNIVERSITY EXAMPLE

how to resume download in chrome | resume failed download in google chrome google drive failed crash

Unfinished degree on your resume?

How to resume failed download in chrome || Resume failed downloading in chrome

Should I Put In An Incomplete Degree On A Resume?

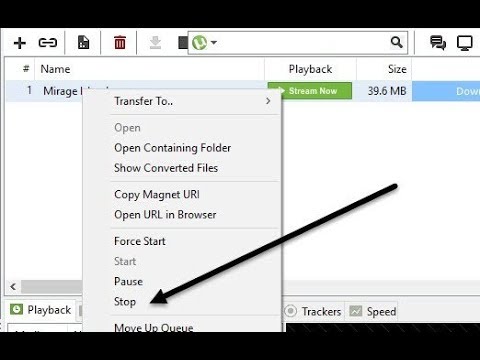

how to resume unfinished download file in Utorrent FIXED

PowerPoint Quick Tip: Recover Unsaved Presentations

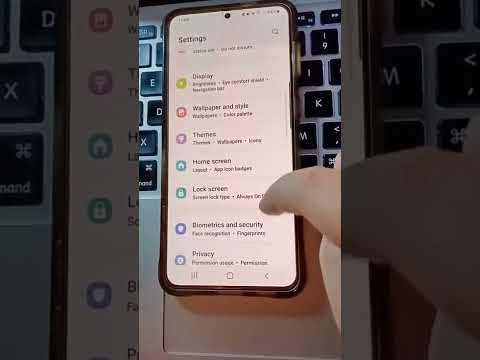

Disable This Android Privacy Setting ASAP!

How to Resume Preparation After a Long Break

How to fix google chrome download failed network error

How to Find Draft Post on Facebook (Easy 2024)

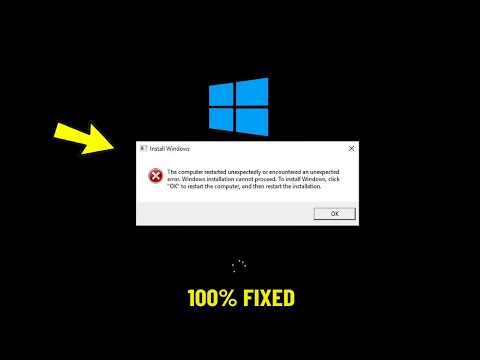

Fix The computer restarted unexpectedly or encountered an unexpected error Windows 10/11/7 ⚠️

Fixed: iCloud Backup Stuck on Estimating Time Remaining [Update Requested]

Delete restoration data and proceed to system boot menu | BIOS update | 100% fix | AUG2020 | Windows

#bl #manhwa #tiktok

Your GPA Doesn’t Matter

How to Resume broken ADM downloads | How to continue unfinished download in ADM

The computer restarted unexpectedly or encountered an unexpected error windows 10 SOLUTION

What If You Turn Off Your PC During An Update?

how to find your unfinished downloads in Chrome

Fix & Speed Up Dead Torrent | Resolve Torrent Shows connecting to peers

Easy Fixed: Data Transfer Cancelled Reset iPhone to start setting up again'

Комментарии

0:10:20

0:10:20

0:11:15

0:11:15

0:02:13

0:02:13

0:04:18

0:04:18

0:01:00

0:01:00

0:04:29

0:04:29

0:01:00

0:01:00

0:05:03

0:05:03

0:01:00

0:01:00

0:00:29

0:00:29

0:01:21

0:01:21

0:01:41

0:01:41

0:00:51

0:00:51

0:01:55

0:01:55

0:04:21

0:04:21

0:03:50

0:03:50

0:00:19

0:00:19

0:00:23

0:00:23

0:01:44

0:01:44

0:02:39

0:02:39

0:05:01

0:05:01

0:00:58

0:00:58

0:02:48

0:02:48

0:02:50

0:02:50