filmov

tv

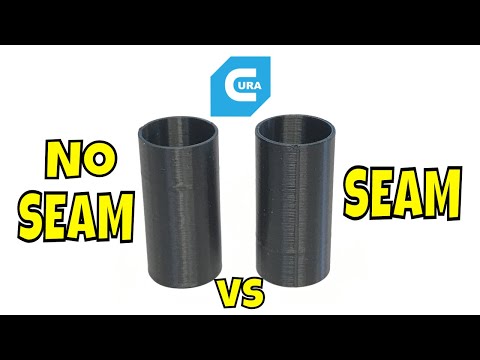

Simple Slicer Change Helped Prevent Warping

Показать описание

Love the channel? Consider supporting me on Patreon:

In todays video we take a look at the Z Seam. I have recently been printing quite a bit of ABS parts for the Voron Switchwire build and ran into some serious issues with some of the parts. After trying quite a few things I was able to narrow down one huge cause of the issue and the solution was quite simple.

(´∀`)♡ As an Amazon Associate I earn from qualifying purchases:

Lets Get Social!

In todays video we take a look at the Z Seam. I have recently been printing quite a bit of ABS parts for the Voron Switchwire build and ran into some serious issues with some of the parts. After trying quite a few things I was able to narrow down one huge cause of the issue and the solution was quite simple.

(´∀`)♡ As an Amazon Associate I earn from qualifying purchases:

Lets Get Social!

Simple Slicer Change Helped Prevent Warping

Adaptive purge for every 3D printer: A simple slicer tweak

Understand WHY 3D prints WARP - Simple explanation with experiment!

3D Print parts TWICE as fast with simple slicer tweaks. 3DP101

5 Slicer defaults I ALWAYS change #3DP101

9 Game Changing Slicer Settings You NEED To Try

The 3 Minute SLICE CURE! Wow This REALLY WORKS!

5 simple ways to fix your golf slice (they work)

Recipe of the Week

1 simple slicer trick slashes hours off your belt printer times (CR30, Infi-20, etc.)

Creality Ender 3 V2 - Simple Tips for Super Clean 3D Prints

Excel Slicer Formatting incl. Hidden Trick to Make them SMALL!

How to Make a Slicer not affect all the Visuals in PowerBI | Edit Interactions | MI Tutorials

THE COMPLETE FIX YOUR SLICE GUIDE - OVERVIEW

3D Print 50% Faster with These Tips! (Slicer Settings)

Perfect 3d Printed Undersides - Dial in your slicer's support settings!

How To Fix A Slice With A Driver (So Simple!)

Help! My Orca Slicer Supports are Hard to Remove and Damage my 3D Print

COVID: Slicer tweaks to help 10x stack come apart easier

How to use ONCE FOR ALL Rapid-prep Mandoline Vegetable Slicer

5in1 Multifunctional Easy Slicer Grater #shorts #cutter #slice #youtubeshorts

How to Control Seams In Cura Slicer Settings

3D printer slicer tips.#superslicer #3dprinting #d3d #3dprint #3dprinttiktok d3design on petreon

How to: STOP slicing the golf ball | REALLY EASY TIPS

Комментарии

0:07:54

0:07:54

0:11:45

0:11:45

0:01:38

0:01:38

0:14:42

0:14:42

0:15:27

0:15:27

0:08:24

0:08:24

0:04:48

0:04:48

0:08:18

0:08:18

0:07:20

0:07:20

0:09:16

0:09:16

0:08:26

0:08:26

0:04:33

0:04:33

0:02:36

0:02:36

0:04:28

0:04:28

0:11:06

0:11:06

0:13:08

0:13:08

0:07:27

0:07:27

0:10:03

0:10:03

0:33:11

0:33:11

0:03:35

0:03:35

0:00:23

0:00:23

0:06:58

0:06:58

0:00:34

0:00:34

0:08:16

0:08:16