filmov

tv

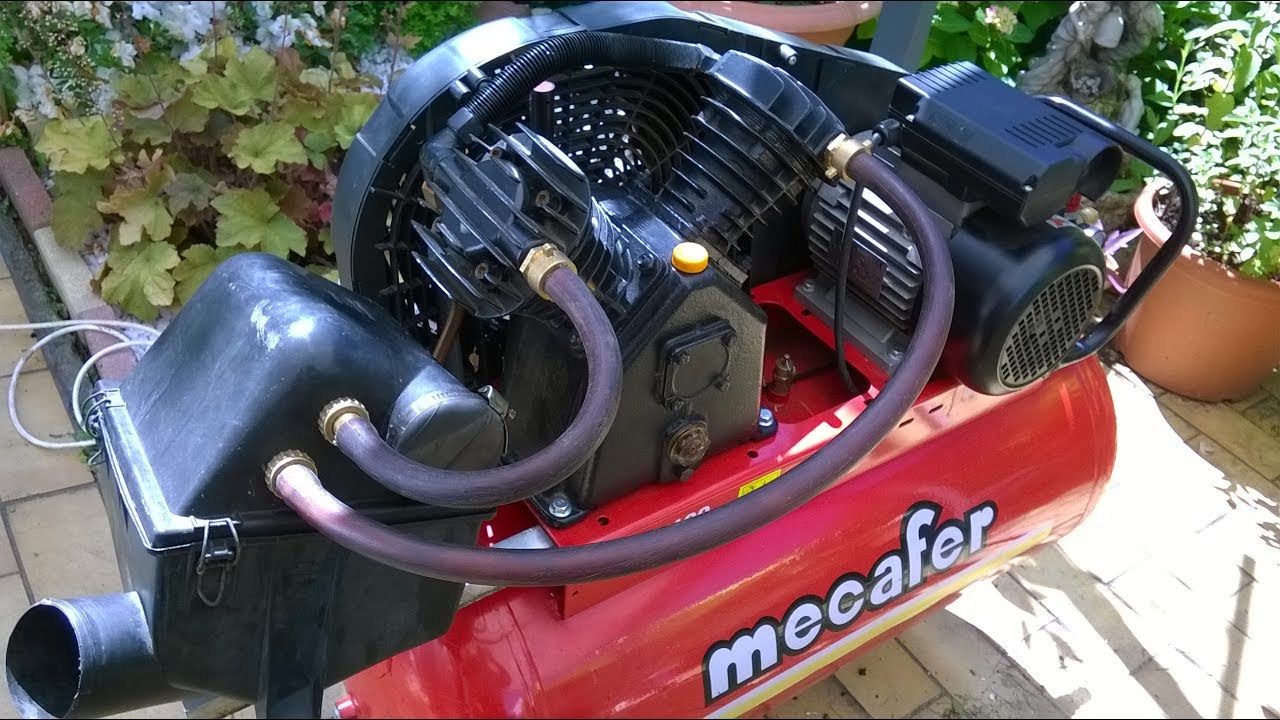

Air compressor : REALLY effective sound reduction modification.

Показать описание

Air compressor : REALLY effective sound reduction modification.

How does an Air Compressor work? (Compressor Types) - Tutorial Pneumatics

What Air Compressor Do You Need? | Harbor Freight

Air Compressor Working Principle | How does an Air compressor work? | (compressor types)

What Size Air Compressor Do You Really Need?

Air Compressor Types, How They Work, and How to Choose the Right One

How a Compressor Works

Silence your air compressor CHEAP!

All Top Air Compressor demo review | Affordable budget overland gear | This thing is FAST

How to Choose and Use Air Compressors | Ask This Old House

*AIR COMPRESSOR WARNING*

The Best Air Compressor Upgrade | Do This For More CFM

✅ Building a Better Air Compressor for My Garage for DIRT CHEAP !

Marine Air Compressor: Parts and Operation Explained | 3D Animated Explanation

Air Compressor Repair - pressure switch, unloader, and check valve

How Air Compressors Work! (Piston Design)

How to Choose an Air Compressor

Quietest Air Compressor - Chicago Air Hush Range #welovetools

The 3D Printed Air Compressor: Will it Work?

Easy Trick to Make Your Air Compressor Quieter

Which Air Compressor? Comparing ABAC, Bambi, Clarke, Hyundai, Orazio, Scheppach, SIP and Swan

Full Shop Air Compressor Setup

Air compressor : effective way to increase flow,impressive results.

Air Compressor Simple Upgrade - CHEAP & EASY - Increase Tank Capacity!

Комментарии

0:13:42

0:13:42

0:04:14

0:04:14

0:02:39

0:02:39

0:05:49

0:05:49

0:15:55

0:15:55

0:16:57

0:16:57

0:03:17

0:03:17

0:05:29

0:05:29

0:03:50

0:03:50

0:04:01

0:04:01

0:04:31

0:04:31

0:10:00

0:10:00

0:23:38

0:23:38

0:05:54

0:05:54

0:03:48

0:03:48

0:06:18

0:06:18

0:07:27

0:07:27

0:00:27

0:00:27

0:08:03

0:08:03

0:05:39

0:05:39

0:09:16

0:09:16

0:15:48

0:15:48

0:07:20

0:07:20

0:10:26

0:10:26