filmov

tv

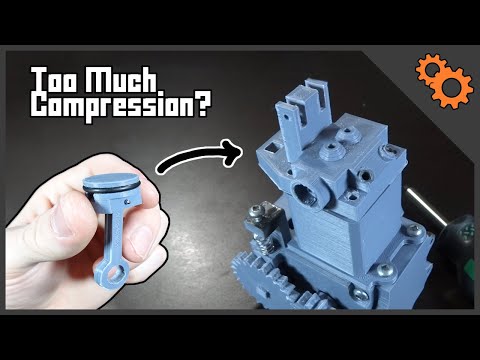

The 3D Printed Air Compressor: Will it Work?

Показать описание

Today, I 3d printed an air compressor. Lets see if it works. Compressors are useful as they can store potential energy as form of compressed air. This pressure can be later released as kinetic energy to run something like a 3d printed air engine for example. The idea is to create a 3d printed air compressor, the design is very similar to that from my 3d printed gas engine. The biggest differences include a piston with more o-rings to hold greater pressure and heads with check valves to work without the need of timing devices.

#3dprinting #engines

The 3D Printed Air Compressor: Will it Work?

Two POWERFUL 3D Printed Axial Compressors - feat. Uniformation GKTwo

3D printed DeWalt air compressors

3D Printed Air Compressor

Painting D&D minis and 3D prints: Iwata Ninja Airbrush Compressor

The Best Airbrush Compressor for Painting 3D Prints

Building a Small and Quiet Air Compressor [4K]

3D Printed Mini Air Compressor Part 1

He Conquers Half the Galaxy in the Mech Age, Designing Mechs to Save His Family’s Legacy 06

3D printed double piston air compressor for balloons, no bearings, screws only.

I 3D Printed a Compressor that ACTUALLY WORKS (but you've never heard of this design)

So you wanna AIRBRUSH 3D printed models huh? Review/ Tips

3D printed double piston air compressor

It Took Me 3 Months To Get This Working - Two-Stage Centrifugal Compressor 100% 3D Printed

How to Make 3D Printed Air Compressor Fitting

Is it Possible to 3D Print WORKING AXIAL COMPRESSOR? - (Testing different blade designs)

Compressed Air Triangular Engine - Wankel Rotary (3D Printed)

Getting HIGH COMPRESSION for the 3D Printed Gas Engine (Part 2)

3d printed compressor ,compressing

3D Printed Radial Compressor #shorts

Best Onboard air compressor hack: make it fit, make it fast.

$30 Laser Air Assist Upgrade/How to guide

How to Design a Better 3d Printed Compressor for our Jet Engine!

DIY 3D Printed Vacuum Impellers

Комментарии

0:08:03

0:08:03

0:11:31

0:11:31

0:00:16

0:00:16

0:11:04

0:11:04

0:02:52

0:02:52

0:10:01

0:10:01

0:20:37

0:20:37

0:00:16

0:00:16

11:53:05

11:53:05

0:04:59

0:04:59

0:08:21

0:08:21

0:13:13

0:13:13

0:00:14

0:00:14

0:11:22

0:11:22

0:05:12

0:05:12

0:13:04

0:13:04

0:14:46

0:14:46

0:07:52

0:07:52

0:00:26

0:00:26

0:00:16

0:00:16

0:08:58

0:08:58

0:08:02

0:08:02

0:09:23

0:09:23

0:11:13

0:11:13